ADDRESSING SUBSEA INTERCONNECT CHALLENGES

Optimizing Data Transmission in Subsea Cable Systems

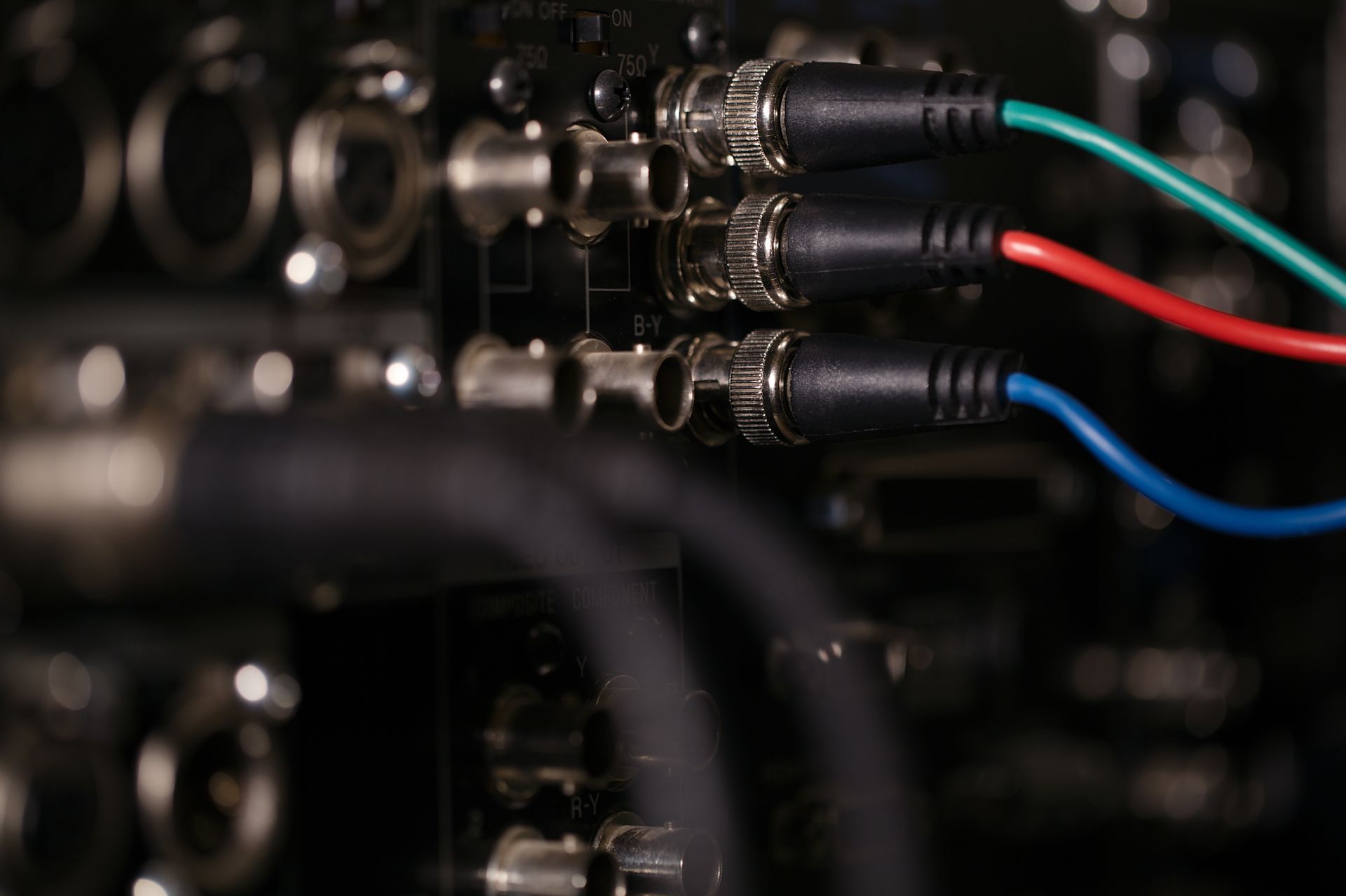

Subsea cable systems form the foundation of digital communication across oceans and deepwater environments. As the demand for higher bandwidth and real-time data in the marine and offshore sectors intensifies, reliable subsea interconnects have become critical infrastructure. These systems must perform under enormous pressure, corrosion, and mechanical stress, delivering stable transmission in some of Earth’s harshest environments.

At Meritec, we engineer marine-grade cable assemblies and interconnects that meet the stringent performance requirements of subsea applications. From offshore energy operations to undersea surveillance, our solutions ensure optimized data transmission, even at extreme depths.

Addressing Subsea Interconnect Challenges

The subsea environment imposes unique electrical, mechanical, and environmental demands. Systems may operate at depths exceeding 6,000 meters, where temperature gradients, hydrostatic pressure, and saltwater corrosion present constant threats to signal integrity and hardware longevity.

Key performance factors for subsea interconnects include:

- High signal integrity over long distances, minimizing attenuation and latency

- Resistance to hydrostatic pressure and dynamic underwater forces

- Reliable sealing against water ingress and particulate intrusion

- Shielding against EMI from onboard systems and external sources

- Material compatibility with seawater and marine biofouling agents

Subsea connectors must also withstand repeated mating cycles, high mechanical loads, and exposure to oil-based fluids in offshore drilling environments. These conditions drive the need for robust material selection, precision assembly, and thorough quality control.

Real-World Subsea Applications

Offshore Energy Infrastructure

Modern offshore oil and gas platforms depend on a dense network of sensors, control systems, and data acquisition modules. Meritec provides rugged subsea cable assemblies for:

- Blowout preventer (BOP) control

- Subsea production system monitoring

- Umbilical interface connectivity

- Subsea power distribution and signal relay

Each connection must function flawlessly to prevent downtime, data loss, or system failure.

Undersea Surveillance and Defense

Navy and defense clients use subsea systems for sonar arrays, towed sensors, unmanned underwater vehicles (UUVs), and permanent acoustic monitoring networks. Our interconnects are tailored for:

- Low-noise data transmission

- Long-term deployment on the seabed

- Compact routing in UUVs and submersibles

Scientific and Oceanographic Research

Underwater observatories and autonomous platforms gather massive volumes of environmental data. Meritec supports research applications with:

- High-speed interconnects for real-time sampling

- Moisture-resistant, low-profile assemblies

- Custom terminations for hybrid instrumentation suites

Engineering for Performance at Depth

Optimizing signal transmission below sea level requires careful engineering from conductor to connector. At Meritec, we develop subsea cable assemblies with features that protect both electrical performance and mechanical durability:

- Overmolded connector housings for watertight integrity and strain relief

- High-density pin configurations to reduce volume while maximizing channel count

- PTFE or PFA insulation materials for thermal and chemical stability

- Double-shielded twisted pairs to preserve signal clarity in noisy environments

- Custom jacketing using marine-grade thermoplastics and polyurethanes

Each cable is manufactured in our U.S.-based facility to ensure process control, tight tolerances, and end-to-end traceability. Testing includes pressure tank trials, signal performance analysis, and salt spray resistance to confirm suitability for deepwater conditions.

Data Integrity Over Long Distances

Signal attenuation becomes a major concern in extended subsea networks. Without proper impedance matching, shielding, and material design, bit errors and packet loss can compromise the system.

Meritec’s assemblies are engineered to ensure:

- Low return loss and insertion loss across long cable runs

- Consistent impedance control for differential pairs

- Minimal crosstalk and EMI vulnerability

We also offer custom hybrid cables that carry power and data through a unified jacket, reducing complexity and weight on subsea umbilicals and risers.

Custom Solutions for Unique Marine Requirements

No two subsea systems are the same. We partner with engineering teams to develop application-specific cable assemblies, tailored to form factors, space constraints, and environmental risks.

Our marine interconnect services include:

- 3D modeling for connector integration

- Custom grommet and strain relief design

- Material compatibility testing with seawater and fuels

- Color coding and keying for easy deployment

From pressure vessels to surface buoys, our assemblies are built to ensure continued uptime, even in turbulent marine environments.

Why Meritec for Subsea Cable Assemblies?

Meritec brings decades of expertise in rugged interconnect engineering to the underwater domain. Our in-house capabilities allow us to:

- Rapidly prototype and refine subsea interconnect concepts

- Apply proven materials from aerospace and defense to marine use cases

- Deliver U.S.-manufactured assemblies with short lead times

- Support full design documentation, testing, and traceability for mission-critical systems

Whether you operate in oil and gas, naval technology, or deep-sea science, Meritec delivers subsea interconnects that hold up to pressure.

Connect with Meritec for Subsea Solutions

Explore our capabilities in marine and subsea interconnect systems. Our team is ready to help you improve data transmission, signal clarity, and long-term reliability beneath the waves.