REDUCING DOWNTIME WITH QUICK-DISCONNECT CONNECTOR SYSTEMS

Reducing equipment downtime is a top priority for manufacturers, field technicians, and systems engineers. In environments where every minute of halted production can mean thousands of dollars lost, connector design plays a crucial role in operational efficiency. Quick-disconnect (QD) connector systems are engineered to solve this problem by minimizing the time and complexity involved in connecting or disconnecting power, signal, or data lines.

These systems are used across a wide range of industries industrial automation, medical equipment, aerospace, transportation, and military where speed, reliability, and repeatability are essential. This blog explores how QD connector systems work, the advantages they offer, and how to choose the right configuration for your specific application.

Understanding Quick Disconnect Connector Systems

Quick-disconnect connectors are designed to allow rapid mating and un-mating of electrical or fluidic connections without tools. These systems use a mechanical interface that clicks, twists, or pushes into place securely. Some use locking mechanisms to ensure vibration resistance and secure engagement.

The core design goals are simplicity, speed, and reliability. Unlike traditional threaded or bolted interfaces, QD systems significantly reduce the steps required for assembly and disassembly. This makes them invaluable in maintenance-heavy or mission-critical environments.

How They Reduce Downtime

The connection process is one of the most time-consuming aspects of equipment installation, maintenance, or reconfiguration. When equipment needs to be repaired or swapped, connectors must be disengaged, checked, and reconnected properly often under time pressure and in less-than-ideal conditions.

QD connectors reduce downtime by:

- Speeding up maintenance – Connectors can be disconnected and reconnected in seconds, often without special tools.

- Reducing installation time – Modular designs allow fast setup of systems with many interconnects.

- Improving troubleshooting – Faulty subsystems can be quickly isolated and replaced.

- Enhancing safety – Lower risk of improper reconnection or incomplete mating.

These benefits are especially important in industries like aviation or industrial automation, where uptime is directly tied to revenue and safety.

Real World Applications Across Industries

Aerospace and Defense: Ground and flight systems use QD connectors to streamline service routines and prevent mission delays. QD interconnects help in situations where rapid access to avionics, sensors, or fuel systems is necessary.

Industrial Automation: In large-scale manufacturing environments, machinery often requires frequent retooling or service. QD systems make it easier to replace sensors, motors, or control units without rewiring.

Medical Devices: Medical carts, imaging systems, and diagnostic machines often use QD connectors to allow fast replacement of cables or modular components, minimizing service downtime in clinical settings.

Transportation: Railway, marine, and heavy vehicle systems benefit from QD interfaces that improve maintainability and reduce repair cycles.

Oil & Gas: Rugged QD connectors support field-deployable instrumentation and quick maintenance in remote and hazardous environments.

Types of Quick-Disconnect Mechanisms

QD connector systems come in various designs, each suited to different environments and use cases:

- Push-Pull Connectors: Engage and disengage with a straight pull motion. Often used in medical and test equipment.

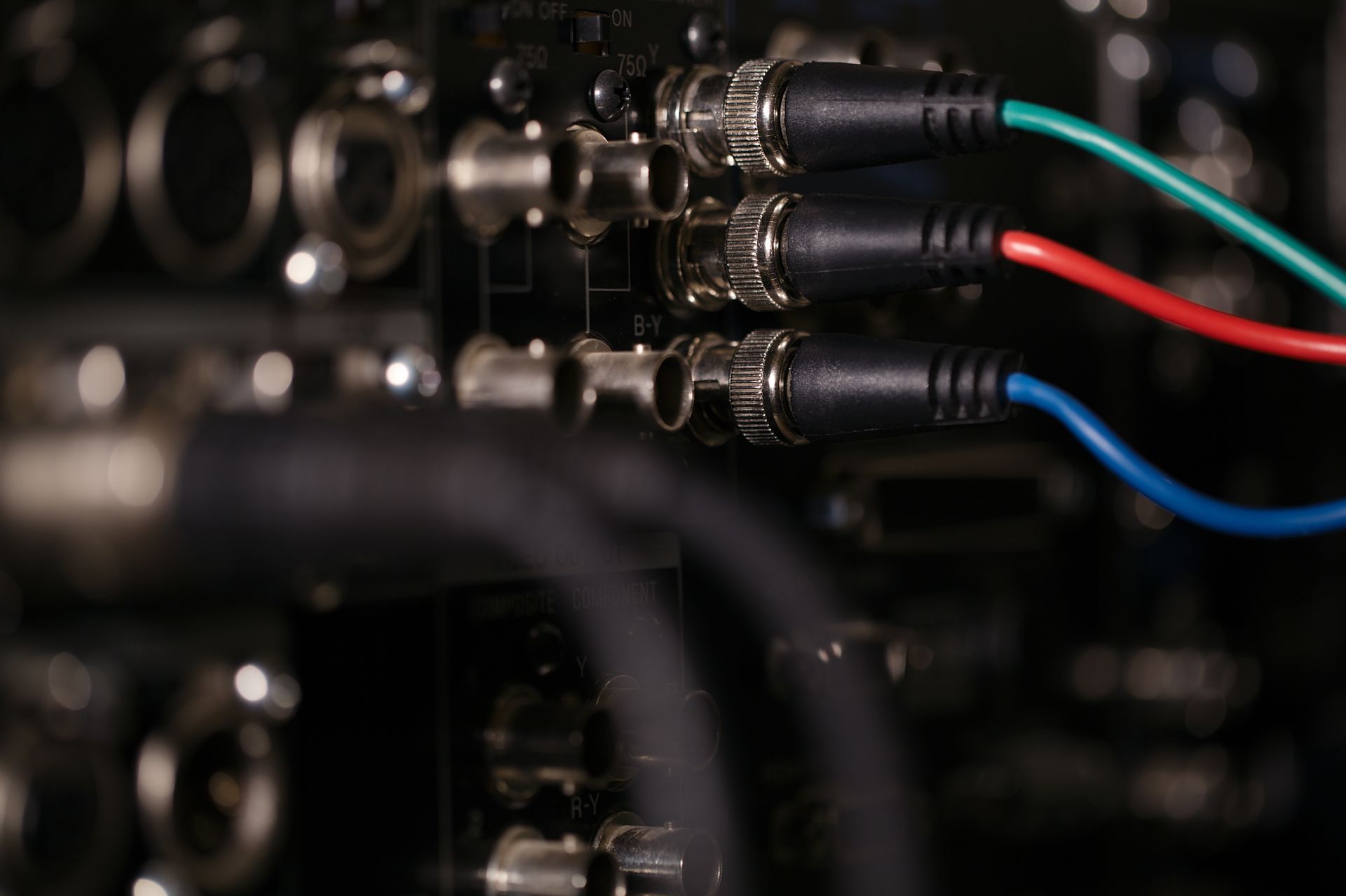

- Bayonet Locking: Use a twist-lock motion for secure mating. Ideal for vibration-prone environments.

- Lever-Actuated Systems: Common in heavy industrial applications where tool-free operation is critical.

- Snap Fit or Click-Lock Designs: Allow instant locking with tactile feedback—useful for field-deployed electronics.

Each mechanism balances speed, security, and resistance to environmental stressors. Material selection (such as stainless steel, aluminum, or high-performance polymers) further tailors the connectors to specific industry demands.

Table: Comparison of QD Connector Types

| Connector Type | Mating Style | Strengths | Common Applications |

|---|---|---|---|

| Push-Pull | Straight Pull | Fast, intuitive, tool-free | Medical, instrumentation |

| Bayonet Lock | Twist Lock | Secure under vibration | Aerospace, automotive |

| Lever-Actuated | Lever Clamp | High retention force, rugged | Industrial machinery |

| Snap/Click-Lock | Push Fit | Quick tactile lock, compact | Portable electronics |

Design Considerations for Maximum Uptime

When specifying QD connectors, engineering teams must balance performance requirements with practical concerns:

- Mating Cycles: High-cycle connectors are essential for equipment that undergoes frequent maintenance.

- Environmental Sealing: IP-rated or hermetically sealed designs protect against dust, moisture, and chemicals.

- EMI/RFI Shielding: For signal integrity in high-noise environments, shielding is non-negotiable.

- Contact Reliability: Gold or nickel plating improves corrosion resistance and conductivity.

- Modular Configurations: Custom or hybrid connector layouts reduce cable clutter and streamline routing.

Meritec offers tailored quick-disconnect solutions to meet the exact requirements of each system, including overmolded options and low-profile configurations that support tight-space installations.

Long-Term Maintenance and Cost Benefits

Over the lifecycle of a system, the ease and speed of QD connectors translate into tangible cost savings. Fewer tools mean faster training for technicians. Reduced risk of improper installation means fewer returns and warranty claims. Standardized modular designs allow inventory to be consolidated across systems.

More importantly, uptime is maximized. That value alone often offsets the slightly higher initial investment in robust QD connector designs. For organizations aiming to improve lean operations, QD connectors support faster turnaround with less disruption.

FAQs: Quick-Disconnect Connector Systems

How much time can QD connectors save during maintenance?

Depending on the number of interfaces and complexity, QD connectors can reduce reconnection time by 50% or more compared to threaded systems.

Are quick-disconnect connectors reliable in harsh environments?

Yes, many are designed to withstand extreme temperatures, shock, vibration, and moisture with appropriate sealing and materials.

Can QD connectors handle high current or data rates?

Advanced QD connectors can be engineered to handle both power and high-speed signal applications with proper shielding and contact design.

Is there a tradeoff between speed and performance?

Not necessarily. When engineered properly, QD connectors offer fast installation without sacrificing performance, especially in mission-critical systems.

Can Meritec Can Meritec customize a QD solution for my system? plating solutions?

Yes. Meritec offers fully customized connector designs, including hybrid, shielded, and overmolded QD systems tailored to your exact application.

Partner With Meritec for Fast, Field-Proven QD Solutions

If reducing downtime is a key performance indicator for your operations, investing in quick-disconnect connector systems is a strategic move. Meritec designs and delivers rugged, high-performance QD solutions tailored to aerospace, industrial, defense, and medical applications. With decades of experience in high-reliability interconnects, our team helps you achieve faster maintenance cycles, safer system designs, and uninterrupted productivit