TRENDS IN HIGH DENSITY INTERCONNECTS FOR SPACE EXPLORATION

In the realm of space exploration, the demand for rugged, compact, and high-performance electronics continues to rise. As aerospace systems evolve from Earth-orbiting satellites to deep-space probes, the importance of high-density interconnect (HDI) solutions grows. These systems must deliver reliable performance under extreme environmental conditions, supporting mission-critical electronics where size, weight, and power are at a premium.

HDI technology empowers engineers to

maximize functionality within confined form factors, maintaining robust signal integrity in the harshest conditions. Whether it’s ensuring stable communication between modules or supporting high-speed data transfers, interconnect design often defines the boundary between success and failure.

The Unique Demands of Space Electronics

Space presents challenges that traditional electronics cannot withstand. Beyond Earth's atmosphere, systems face radiation exposure, vacuum, and extreme thermal cycling. These factors stress every component especially the interconnects.

Unlike terrestrial devices, there’s no opportunity to perform on-site maintenance in orbit. Aerospace electronics are expected to function reliably for years, enduring high-G launches and zero-gravity operations. HDI systems must be engineered to resist mechanical shock, thermal fatigue, and signal loss under these grueling conditions. Every connector and cable must perform flawlessly from liftoff to mission completion.

Why High-Density Interconnects Are Mission-Critical

HDI systems provide a powerful advantage in space: they handle complex signal architectures without compromising space or weight. With fine-pitch routing, stacked microvias, and multilayer PCB configurations, they offer compact, high-performance designs optimized for modern aerospace platforms.

They also improve reliability. Fewer components mean fewer potential failure points. Shorter trace lengths reduce delay and cross-talk crucial for real-time communications, navigation, and sensor feedback. As data speed requirements increase, HDI assemblies remain a cornerstone of aerospace innovation.

Aerospace HDI Design Innovations

Space-grade HDI design begins with rigorous modeling and simulation, accounting for vibration, radiation, thermal cycles, and pressure changes. Engineers now implement blind and buried vias alongside staggered microvias to maintain high routing density while ensuring mechanical resilience.

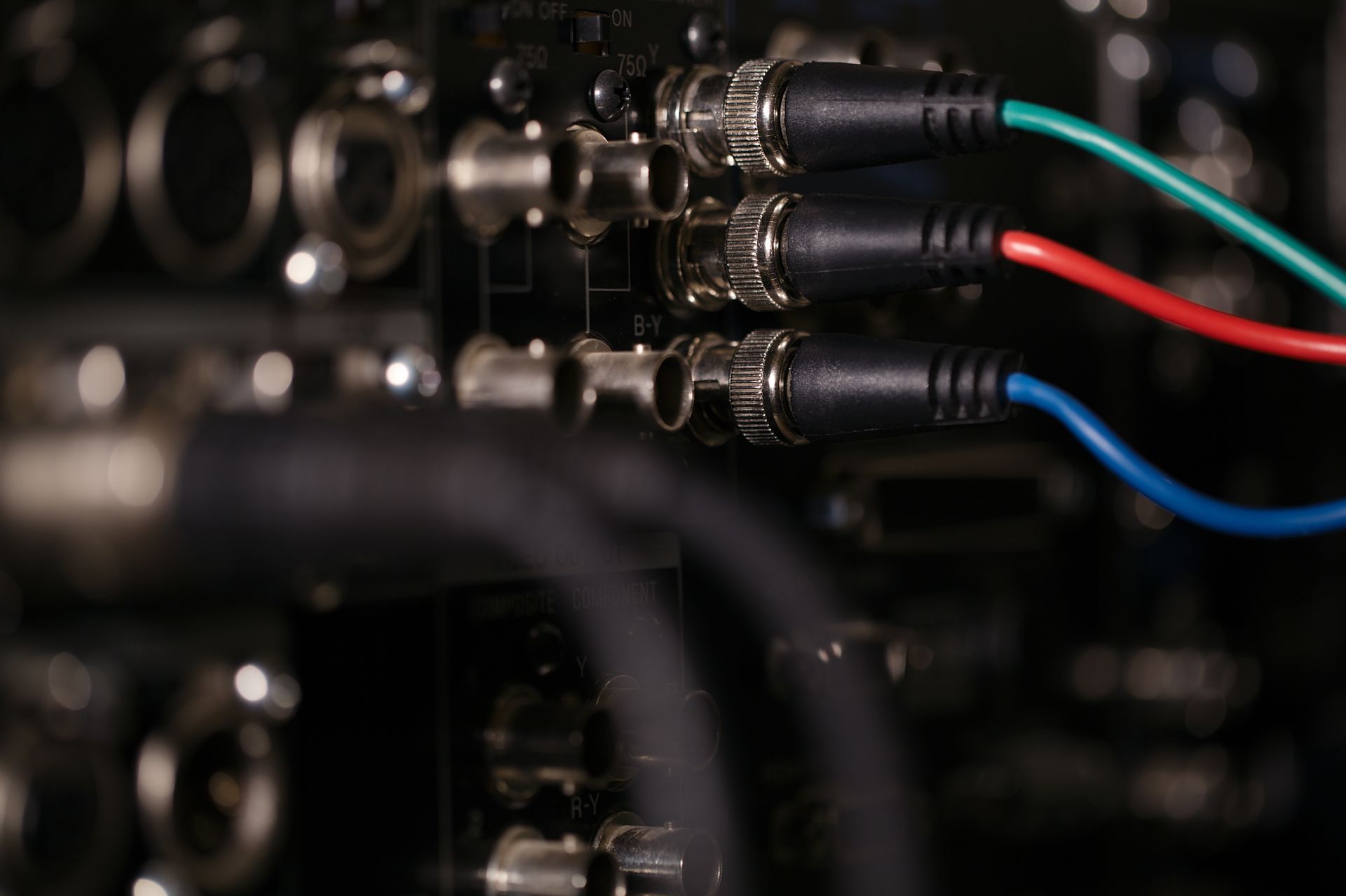

Material science is also advancing. Designers are choosing PTFE-based substrates and low-loss dielectrics, especially for high-frequency or RF applications. In parallel, connectors have evolved to surface-mount, edge-launch, and micro-coaxial forms to reduce bulk and enhance performance.

Cable assemblies and PCBs are often co-engineered to form fully integrated interconnect systems. This unified approach ensures that every signal transition point board to cable, cable to connector is robust, shielded, and optimized for space conditions.

The Impact of Miniaturization and Modularity

Modern aerospace systems from CubeSats to orbital science platforms rely on modular, lightweight electronics. HDI enables the stacking and folding of electronics into multidimensional layouts, freeing designers from single-plane restrictions.

Smaller payloads require fewer harnesses and more integrated boards. A shift to multi-functional PCBs with embedded interconnects has become the norm, allowing signal routes to remain clean and direct despite reduced real estate. These compact designs are vital in modular systems that need to swap or upgrade components in orbit without reengineering entire payloads.

As missions increasingly rely on AI, real-time telemetry, and autonomous navigation, the data burden expands. HDI systems are uniquely equipped to meet the growing bandwidth demands within constrained footprints.

Space-Grade Materials and Plating Innovations

Choosing the right substrate and finish is essential for long-term reliability in space. Conventional FR4 often falls short in radiation-heavy or cryogenic conditions. Instead, engineers turn to polyimide, PTFE, and ceramic-polymer hybrids.

Surface finishes are equally critical. ENIG plating, gold over nickel, and tin-lead soldering help reduce oxidation and thermal fatigue. These materials protect the conductive paths from vacuum-induced outgassing, radiation decay, and mechanical shifts during mission events.

Below is a summary of material choices and performance benefits:

| Material / Plating Type | Application Suitability | Key Benefits |

|---|---|---|

| Polyimide Substrate | Radiation-heavy environments | Thermal stability, durability |

| PTFE Dielectric | RF/Microwave systems | Low signal loss, high frequency support |

| ENIG (Gold/Nickel) | Connectors and pads | Corrosion resistance, signal reliability |

| Tin-Lead Solder | Solder joints in vacuum | Thermal fatigue resistance, proven legacy use |

| Ceramic-Polymer Hybrids | High-power payloads | Low outgassing, structural strength |

These materials help define the mission lifecycle of aerospace electronics. The right combination of conductors, dielectrics, and plating directly influences thermal tolerance, signal quality, and mechanical durability.

Testing and Qualification for HDI in Space

Space-bound HDI systems are qualified through rigorous aerospace and defense standards. Testing protocols evaluate not only basic electrical continuity but also EMI shielding, shock and vibration resistance, and vacuum stability.

Thermal cycling, radiation simulation, and vibration testing replicate launch and orbital conditions. Engineers analyze signal degradation, solder joint durability, and connector resilience across thousands of simulated flight hours.

These qualification procedures are essential to ensuring that interconnects won’t degrade over time. The consequences of a failed interconnect in orbit can be mission-ending there’s no margin for error.

Meritec’s Role in Aerospace HDI Solutions

Meritec is deeply invested in advancing HDI technologies for space exploration. Our aerospace-grade cable assemblies, flex circuits, and rugged connectors are engineered for mission-critical reliability.

From communications satellites to robotic landers, Meritec products are deployed across systems where size, weight, and signal integrity matter most. Our U.S.-based engineering teams collaborate with aerospace clients from concept through qualification, ensuring each product meets specific application demands.

Meritec’s aerospace portfolio includes:

- High-density coaxial cable assemblies for RF communications

- Multi-drop and stacked ribbon solutions for compact routing

- Shielded flex circuits for high-mobility payloads

- Custom micro-coax and twinax configurations optimized for signal clarity

Each solution is backed by decades of experience in defense, avionics, and rugged computing. Our in-house testing labs provide environmental simulation, signal integrity validation, and thermal stress analysis tailored to the aerospace sector.

Looking Forward: What’s Next in HDI for Space

The next generation of space missions will integrate AI, edge computing, sensor fusion, and optical communication. These advancements will place new demands on interconnect design requirements for even smaller footprints, higher bandwidth, and ultra-low power draw.

Emerging trends include:

- Optical fiber interconnects to replace copper where electrical performance plateaus

- 3D-printed and additive interconnect structures for conformal electronics

- Integrated thermal management using novel materials

- Smart interconnects capable of self-monitoring for temperature or radiation exposure

Meritec is already developing systems for these frontiers. Our R&D teams are engaged with partners across defense and aerospace sectors to build the next wave of interconnects that power intelligent, autonomous spacecraft.

We’re not only designing for today’s missions we’re engineering for what’s next.

Trusted Interconnects for Critical Aerospace Missions

At Meritec, we understand what’s at stake in space. That’s why we design interconnect systems that exceed mission requirements for durability, signal integrity, and environmental resilience.

If you're building next-gen satellites, rovers, or deep-space systems, Meritec can help ensure your interconnects support performance from launch to reentry or beyond.

FAQs: High-Density Interconnects for Space Exploration

What makes HDI systems suitable for space applications?

HDI systems are designed for compactness, high-speed signaling, and mechanical durability. Their layered construction, fine-pitch traces, and advanced materials make them ideal for radiation, vacuum, and vibration environments.

What materials are commonly used in space-qualified interconnects?

Polyimide, PTFE, and ceramic-polymer hybrids are favored due to their heat resistance, low outgassing, and stability under radiation. ENIG and gold plating are standard for ensuring contact reliability.

How does HDI contribute to satellite miniaturization?

By integrating more functions on fewer layers and allowing compact routing, HDI enables smaller, lighter electronics critical for reducing payload weight and increasing launch efficiency.

How are Meritec’s products tested for aerospace use?

Meritec conducts vibration, thermal cycling, and radiation exposure tests, ensuring compliance with MIL-SPEC and NASA-level standards. Each product is validated for mission-specific conditions.

What future trends are shaping HDI in aerospace?

Optical interconnects, embedded sensors, and 3D-printed circuit structures are on the horizon. These advances aim to meet the increasing demand for data speed, low latency, and extreme reliability.