CABLE ASSEMBLIES VS WIRE HARNESSES: WHAT’S THE DIFFERENCE AND WHY IT MATTERS

Introduction: Terminology That Matters

In high-performance engineering environments, whether in aerospace, defense, robotics, or industrial automation, the terms “cable assembly” and “wire harness” are often used interchangeably. But for system designers and integrators focused on precision, reliability, and performance, the distinction isn’t just semantics. It’s critical.

At Meritec, we build advanced

cable assemblies

designed to meet the challenges of high-speed data transmission, EMI control, and environmental exposure. Understanding how they differ from traditional wire harnesses helps our customers make more informed decisions, and avoid costly performance issues down the road.

Defining the Basics: Cable Assembly vs. Wire Harness

Let’s begin with definitions. A wire harness typically refers to a grouping of wires bundled together to transmit electrical power or signals in basic circuits. The conductors are usually enclosed in some form of exterior wrap or conduit and terminated with simple connectors. These are commonly used in household appliances, automotive interiors, or control panels where mechanical stress is minimal and EMI exposure is limited.

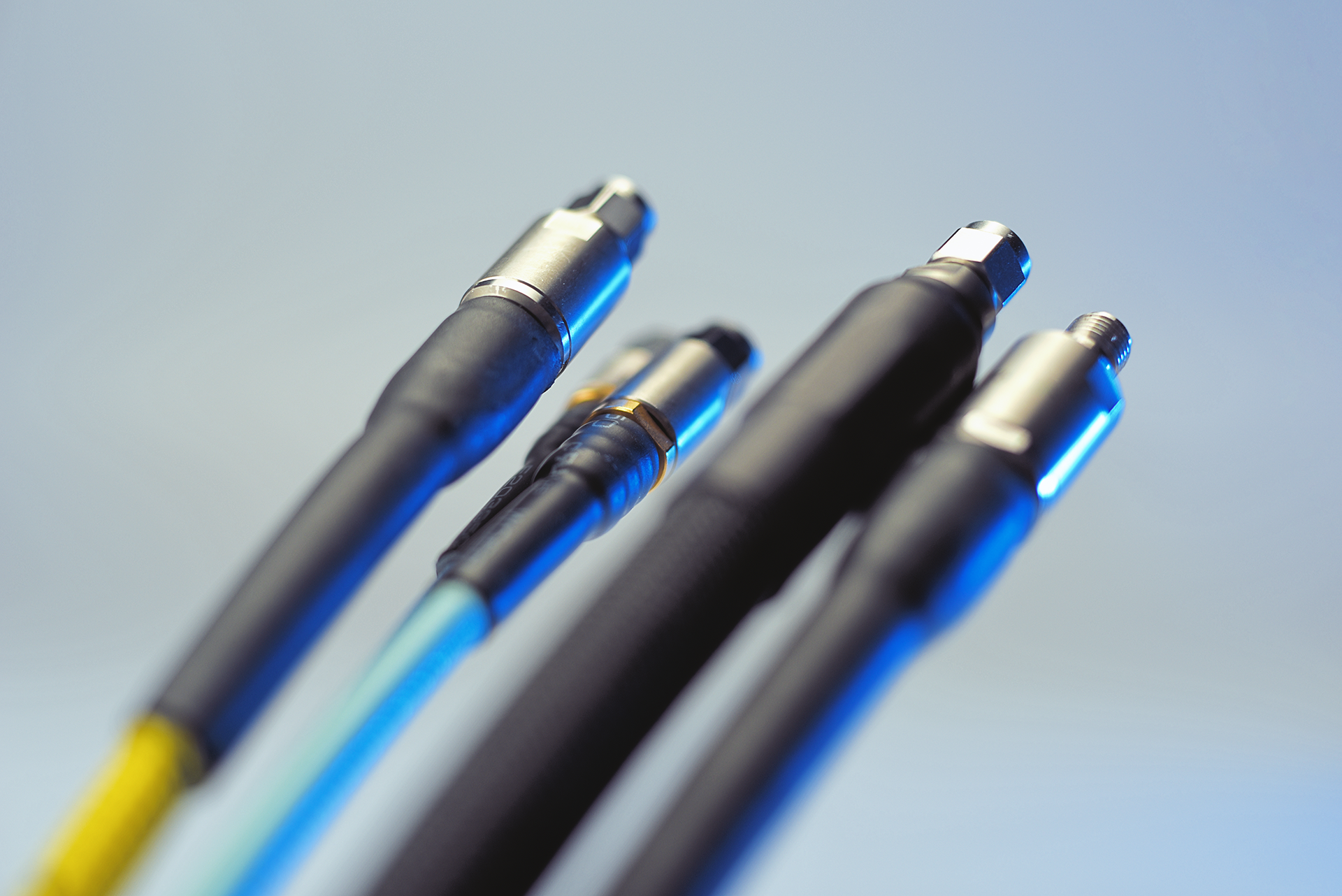

In contrast, a cable assembly incorporates not just wires or conductors, but also shielding, insulation, and ruggedized external sheathing. The cables are often twisted or paired to reduce crosstalk and preserve signal integrity, and the assembly is designed with specific electrical, mechanical, and environmental performance characteristics in mind.

At a glance, both may look similar, but their

purpose, build quality, and application readiness

are vastly different.

Why the Difference Matters in High-Speed Applications

For simple power distribution or analog signal switching, a basic wire harness might suffice. But once you're dealing with high-frequency digital signals, differential pairs, or mission-critical environments, a wire harness becomes a liability.

Cable assemblies are engineered to maintain consistent impedance, minimize insertion and return loss, and withstand external factors like temperature cycling, vibration, shock, or fluid ingress. This level of protection is essential in systems running protocols such as PCIe, USB 3.0, SATA, or 10G Ethernet.

Consider a flight data recorder on a commercial aircraft. A minor signal integrity failure could corrupt sensor logs or delay real-time data transfer. In this case, the shielding, grounding, and thermal resilience of a Meritec cable assembly are far superior to what a basic harness could ever support.

Build Structure: What Goes Into Each

A wire harness is typically made by grouping individual wires, applying simple insulation (such as tape or tubing), and crimping or soldering low-complexity connectors. These are often manually assembled and ideal for low-speed, short-distance applications where cost is the primary concern.

A cable assembly, on the other hand, is a precision-engineered solution. Conductors may be twisted into differential pairs, embedded in shielding foils or braided mesh, and overmolded for strain relief and mechanical retention. The cables are terminated with high-density, high-performance connectors tested for insertion loss, EMI shielding, and durability over thousands of mating cycles.

While a harness can be put together quickly, a cable assembly requires

design expertise, testing protocols, and material science,

especially when performance and compliance matter.

When to Choose One Over the Other

If you’re building a consumer product with short internal wire runs and low data speeds, a wire harness might meet your needs. They're cost-effective and easy to integrate where mechanical and electrical demands are minimal.

However, for anything involving high-speed signaling, repeated motion, environmental stress, or compliance requirements (MIL-DTL, IPC/WHMA-A-620, etc.), a custom cable assembly is the only responsible choice.

Systems that benefit from cable assemblies include:

- Avionics and aerospace computing systems

- Tactical communications hardware

- High-speed test instrumentation

- Robotics and autonomous navigation platforms

- Industrial control networks with real-time feedback

A Real-World Application Example

A medical OEM developing a next-generation imaging system recently approached Meritec. Their prototype was using wire harnesses to connect modular boards and sensors. However, as bandwidth requirements increased, they began experiencing latency and EMI-related noise, disrupting image clarity and real-time control.

Meritec stepped in with a redesigned cable assembly solution that featured tightly twisted differential pairs, 360° EMI shielding, low-skew routing, and custom strain-relieved overmolding. The result? Cleaner signals, faster frame rates, and zero data errors during thermal and vibration testing. What began as a harness retrofit became a long-term production partnership.

Compliance, Testing, and Traceability

Another major distinction between harnesses and cable assemblies is the level of compliance and traceability built into the production process. Wire harnesses are often produced under general manufacturing tolerances with limited performance testing.

Meritec cable assemblies, however, are built under strict IPC/WHMA-A-620 Class II or III standards, and in many cases tested for:

- Continuity and insulation resistance

- Insertion and return loss

- Crosstalk and skew performance

- EMI shielding effectiveness

- Mechanical strain and retention force

- Thermal cycling and fluid resistance

Documentation includes part-specific inspection records, test reports, and CAD models, especially important for aerospace and defense programs with long lifecycle and service documentation needs.

The Meritec Advantage: Engineer-to-Engineer Design Support

What makes Meritec’s cable assemblies stand apart isn’t just the materials or processes, it’s the partnership. We work directly with engineers to understand their system goals and constraints.

Whether you're designing for size, signal quality, or environmental survivability, we help tailor a cable assembly that performs exactly as needed. This includes hybrid layouts combining power and data, custom jackets for abrasion resistance, EMI suppression strategies, and overmolded solutions that meet your dimensional envelope.

You’re not just buying a part, you’re engineering a pathway for system reliability.

Avoiding Common Pitfalls

A common mistake in early-stage system design is assuming a wire harness will suffice because it "connects the pins." But what it doesn’t do, like shielding against RF noise, handling thermal cycling, or maintaining consistent impedance, can cause system failures that are expensive to trace and fix later.

Selecting a cable assembly up front often avoids:

- Signal degradation in long runs or tight bends

- Unexpected EMI in mixed-signal environments

- Mechanical failure from movement or vibration

- Redesign delays from failing compliance tests

Conclusion: The Right Tool for the Right Job

While wire harnesses and cable assemblies might appear similar at first glance, they are fundamentally different tools built for different tasks. When performance, safety, and signal quality are on the line, cable assemblies offer unmatched advantages.

At Meritec, we don’t believe in generic solutions for critical systems. That’s why we focus on building custom cable assemblies that help you deliver reliable, compliant, high-performance hardware, whether you're on the ground, in the air, or pushing the edge of speed and signal clarity.

Explore or Contact Us

Learn more about Meritec’s custom cable assemblies:

Connect directly with Meritec engineering: