CHOOSING BETWEEN COPPER AND FIBER IN HARSH-ENVIRONMENT ASSEMBLIES

Introduction: Making the Right Choice in Demanding Conditions

In rugged applications where extreme temperatures, vibration, moisture, and EMI are common engineers must choose between copper and fiber optic cable assemblies with precision. These environments are often unforgiving, demanding not only durability but consistent performance over time. For sectors such as aerospace, military, oil and gas, and industrial automation, the wrong interconnect choice can compromise an entire system’s reliability.

Meritec

addresses these challenges by offering both high-performance copper and fiber cable assembly solutions that are engineered for ruggedness, flexibility, and long-term signal integrity. This article explores key technical considerations for choosing between the two in harsh conditions and how Meritec supports both with advanced ruggedization techniques.

Signal Performance: Bandwidth, Distance, and Integrity

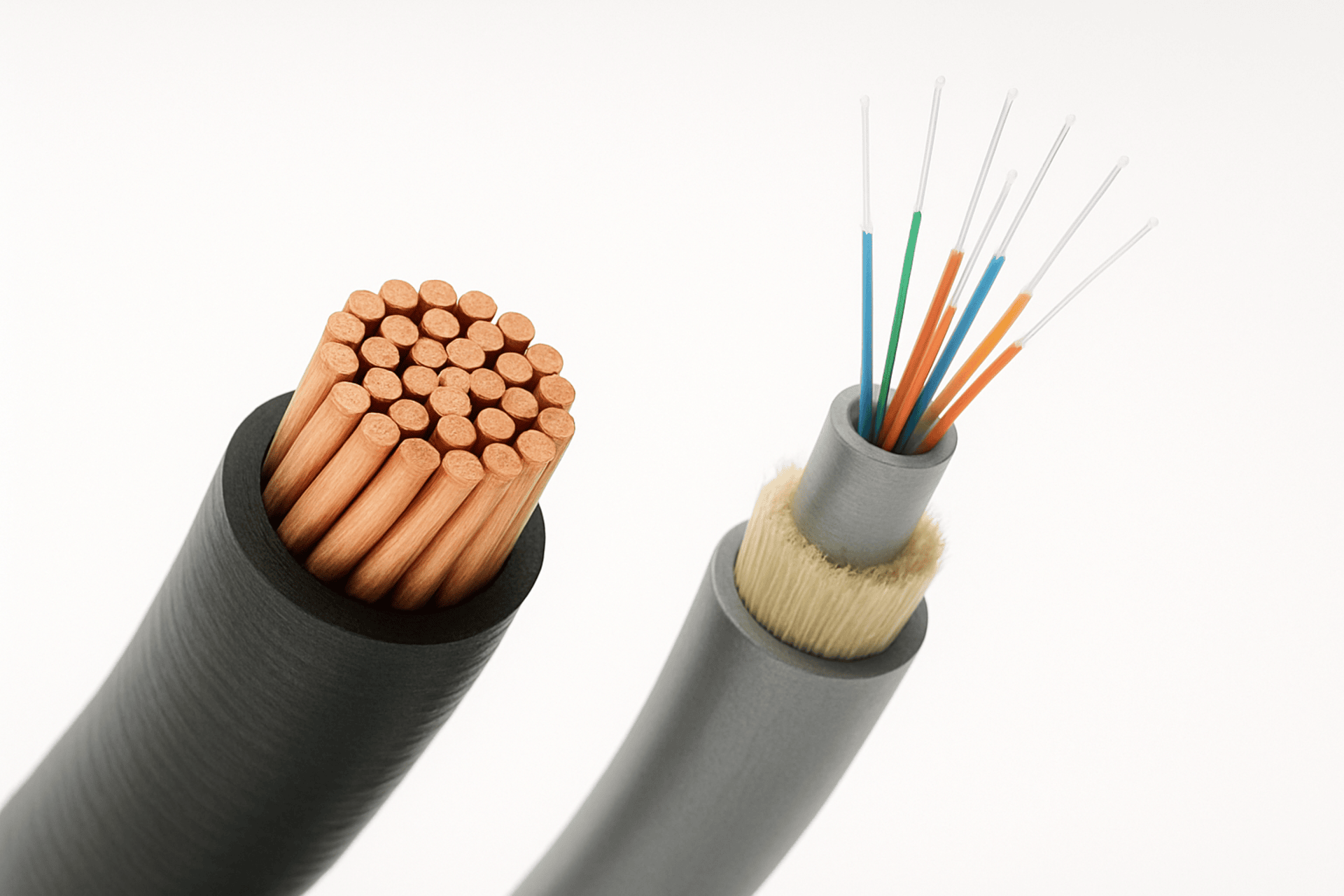

One of the most defining differences between copper and fiber lies in signal performance.

Fiber optic assemblies

use light to transmit data, making them immune to electromagnetic interference (EMI). They support significantly higher bandwidth and can transmit over longer distances without degradation. In contrast,

copper cable assemblies

use electrical signals, which are inherently more susceptible to EMI and signal loss over distance. However, in short-run applications especially those requiring power delivery copper remains highly effective and cost-efficient.

| Parameter | Copper Cable Assemblies | Fiber Optic Cable Assemblies |

|---|---|---|

| Bandwidth | Moderate | Very High |

| Transmission Distance | Short to Medium | Long |

| EMI Resistance | Moderate (with shielding) | Excellent |

| Power Transmission | Supports power + signal | Signal only |

In rugged environments, signal integrity is not just a bonus,it’s a requirement. While fiber excels in raw data rates,

Meritec’s EMI-shielded copper solutions

reduce noise and preserve integrity even in high-vibration, electrically noisy conditions. On the fiber side, we use ruggedized terminations and hermetically sealed connectors to ensure optical integrity even in moisture-prone or high-altitude conditions.

Durability and Environmental Resistance

Durability is another critical factor in rugged applications. Fiber optic cables are made from glass or plastic fibers and are naturally more fragile compared to solid copper conductors. However, modern rugged fiber cables are encased in reinforced jacketing, often with Kevlar or steel braiding to resist crush and pull forces.

Copper, by nature, is more mechanically robust and less sensitive to bending and pulling. Meritec leverages this strength by integrating high-flex copper conductors, sealed overmolds, and strain reliefs to withstand repetitive motion, shock, and abrasion.

Harsh-Environment Challenges Addressed by Meritec:

- Moisture and Particulate Intrusion: IP67/IP68-rated sealing across both copper and fiber assemblies.

- Temperature Extremes: Materials rated from -55°C to +125°C or higher.

- Mechanical Stress: High-flex jacket materials and bonded strain reliefs.

- EMI/RFI Exposure: Multilayer shielding in copper assemblies; optical immunity in fiber.

Size and Weight: A Growing Concern in Aerospace and Military Platforms

In aerospace, military, and UAV systems, space and weight constraints have become design priorities. Fiber optics offer a compelling advantage here: they are lighter and thinner than equivalent copper cables for the same bandwidth. This weight savings can make a significant difference in fuel efficiency and heat generation in aircraft or compact mobile systems.

However, in applications where space savings must be balanced with power delivery such as in embedded avionics or vehicle communication systems copper remains more versatile.

Meritec’s micro coax and fine-pitch assemblies

allow compact, multi-conductor copper designs that rival fiber in size while providing both power and signal in a single bundle.

Installation Complexity and Maintenance

Installing rugged cable assemblies in confined or exposed areas can be challenging, especially if field serviceability is required.

- Fiber assemblies are more delicate during installation and require careful handling to avoid damage to cores or end faces. Bending radii must be strictly followed.

- Copper assemblies are generally more forgiving. They can tolerate tighter bend radii, are easier to route, and don’t require special cleaning procedures.

Meritec supports both technologies with

custom lengths, molded backshells, and connector options that simplify field installation. Additionally, our

PCB-to-cable interconnect solutions

for both copper and fiber help reduce the number of cable terminations required in constrained embedded spaces.

Cost Considerations: Balancing Budget with Performance

While cost should never compromise reliability in critical applications, it remains an important decision factor.

- Copper cable assemblies tend to be more cost-effective, especially at shorter lengths or in power+signal applications.

- Fiber optics typically carry higher upfront costs, not only for the cable itself but for transceivers, polishing, and testing requirements.

That said, the total cost of ownership must be considered. In EMI-intensive environments, for example, copper cables may require extensive shielding or error correction circuits. Fiber, while more expensive upfront, may reduce the need for those components and offer superior long-term reliability.

Meritec helps customers evaluate total system cost

factoring in installation, environmental risk, and expected lifespan when designing custom cable assemblies.

Application Suitability by Sector

Different industries lean toward one technology over the other based on performance demands and environmental exposures. Here's a breakdown:

| Industry/Application | Preferred Technology | Reasoning |

|---|---|---|

| Military & Defense Comms | Fiber or Copper | EMI immunity (fiber) or hybrid data/power (copper) |

| Avionics & Aerospace | Fiber | Weight and bandwidth advantages |

| Industrial Automation | Copper | Robustness and power delivery |

| Oil & Gas | Fiber | Long-distance and EMI resistance |

| Embedded Systems | Copper | High-density, board-level routing |

Meritec’s Dual-Technology Advantage

Meritec offers full engineering support for both rugged copper and fiber optic assemblies. Our in-house design and manufacturing capabilities allow us to deliver:

- Shielded copper interconnects with precision overmolding, strain relief, and EMI control

- Fiber solutions with ruggedized connectors, sealed boots, and custom jacketing

- Hybrid copper/fiber solutions for systems requiring both power and high-speed data

- Compatibility with industry-standard connectors including MIL-DTL-38999, VITA 67, and custom IP-rated terminations

We also provide full testing and validation services, including signal integrity testing, vibration testing, and IP certification to ensure your cable assembly is qualified for the environment it will face.

Conclusion: Selecting the Right Technology for the Mission

In rugged applications, no single cable technology is superior across all metrics. The decision between copper and fiber depends on a range of factors signal type, distance, EMI exposure, weight sensitivity, and environmental durability.

Copper cable assemblies offer better power delivery, lower cost, and robustness in dynamic motion environments.

Fiber optic cable assemblies deliver unmatched EMI immunity and bandwidth in lightweight, sealed packages.

Meritec is uniquely positioned to help OEMs navigate these trade-offs. Our engineering teams work closely with customers to recommend or custom-build

the right rugged cable assembly

whether copper, fiber, or a hybrid tailored to their application’s mechanical, electrical, and environmental constraints.