FLEXIBLE FLAT CABLE ASSEMBLIES (FFC): THE COMPACT SOLUTION FOR HIGH-SPEED SYSTEMS

Introduction: Designing for Compact, High-Performance Systems

Modern systems are getting smaller, faster, and more complex. Engineers are being asked to pack more functionality into tighter spaces without sacrificing performance. Whether it's a portable diagnostic device, a high-speed communications module, or an embedded computing node in aerospace equipment, efficient routing of signals is often the limiting factor.

Flexible flat cable (FFC) assemblies are answering that challenge. With their slim profile, foldable geometry, and high data capacity, FFCs help engineers simplify internal layouts, reduce system weight, and achieve better signal control. At Meritec, we specialize in engineering FFC assemblies that go beyond commodity ribbon cables. Our flat cable solutions are built for signal integrity, environmental resilience, and long-term mechanical performance.

What Makes an FFC Assembly Unique?

Unlike traditional round cables or bulky wire harnesses, flexible flat cables feature a laminated ribbon of conductors arranged in a parallel structure. This configuration allows for consistent spacing between traces, uniform impedance, and a thin overall profile that can be bent, folded, or routed through extremely tight spaces.

The materials used in FFCs, such as polyimide or polyester, are chosen for their thermal and mechanical stability. Combined with precision manufacturing techniques, these materials enable the construction of interconnects that are not only flexible but capable of supporting high-speed data without distortion or loss.

FFC assemblies are often misunderstood as simple solutions for low-end applications. But when engineered properly, they deliver the electrical and mechanical performance required by high-end embedded systems. The key is in the design, tailoring the conductor geometry, insulation, termination, and shielding to the exact needs of the application.

Applications Where FFC Shines

Engineers turn to FFCs when conventional cables are too bulky, too stiff, or too noisy. In handheld or portable medical devices, for example, there's little room for traditional wire routing. An FFC can fold behind display panels, wrap around internal structures, and still carry USB or high-speed video signals without interference.

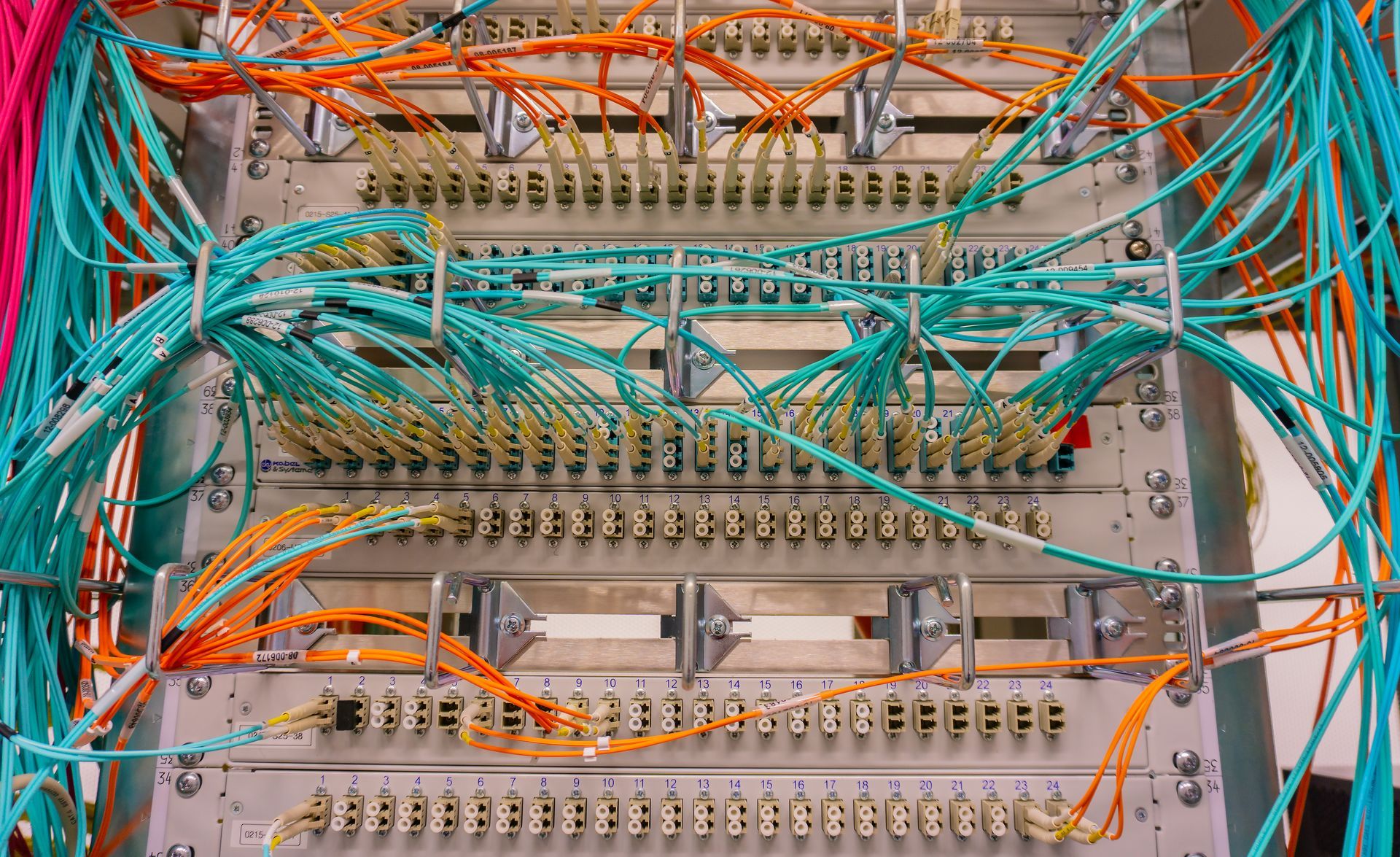

Telecommunications systems benefit from FFCs in their internal architecture. Rack-mounted equipment and baseband units often have modules that need to connect across short distances without introducing airflow obstruction or mechanical clutter. FFCs provide a clean, lightweight solution that integrates well with sliding trays and board connectors.

Aerospace designs push every interconnect to meet both electrical and mechanical thresholds. Flat cable assemblies are now used in avionics suites, where shock and vibration are present but space is extremely limited. FFCs can be folded into layers, terminated to rugged board connectors, and secured against movement, all while delivering high-frequency signals with minimal EMI issues.

How Meritec Designs FFCs for Demanding Systems

At Meritec, every FFC assembly is the result of a collaborative design process. We don’t offer one-size-fits-all ribbons, we build assemblies based on your layout, your signal profile, and your environmental constraints. Our team works directly with engineers to define signal types, trace spacing, dielectric properties, impedance targets, and connector formats.

This level of customization means the final assembly integrates cleanly into your enclosure, maintains signal integrity under mechanical stress, and meets the form factor requirements of your application.

If your system requires mixed signals, combining power and data in one cable, or has specific EMI concerns, we can incorporate shielding layers, ground planes, and optimized trace routing to prevent interference. Whether you're working with LVDS, USB 3.x, MIPI, or PCIe, our flat cable solutions are built to support clean, reliable transmission.

Real-World Problem Solving: A Case from the Field

A customer designing a portable imaging system approached Meritec with a problem. Their prototype used round cables to connect a camera module to the main board, but the routing interfered with airflow and introduced EMI issues during testing. In addition, the cable’s bend radius limited how compact the enclosure could be.

Meritec developed a flat cable solution that combined high-speed signal lines with power conductors in a single laminated structure. The cable folded neatly along a 90-degree internal edge, reducing the system height by over 10 mm. With shielding integrated into the construction and strain relief built into the termination points, the new assembly passed all EMI and thermal cycling tests on the first try.

What started as a retrofit quickly became the production standard, simplifying assembly, improving signal clarity, and allowing the customer to meet both regulatory and physical design goals.

Performance Characteristics Beyond Flexibility

While the main appeal of FFCs is their flexibility and size, Meritec designs them for much more. Each assembly is tested for impedance control, continuity, and insulation resistance. Shielding effectiveness is validated during prototyping and production. Environmental exposure is also considered, meaning materials are selected for chemical resistance, thermal performance, and mechanical durability.

We also help address installation needs. Some customers require peel-and-stick backing for temporary routing; others need overmolded grips to make mating easier in the field. Whatever the mechanical and handling requirements are, we integrate them into the assembly from the start.

Integrating FFCs into Your Product Development

The earlier Meritec is brought into your development cycle, the more value we can offer. Our engineering team supports layout reviews, provides CAD models, and helps optimize board interfaces for flat cable routing. We assist with trace spacing decisions, grounding strategies, and connector mating geometries.

This collaborative approach helps reduce prototyping cycles and minimizes the risk of mechanical interference, impedance mismatch, or connector misalignment. By working with your mechanical and electrical engineers simultaneously, we create assemblies that fit and perform, right out of the box.

Why Leading Engineers Rely on Meritec for Flat Cable Solutions

The engineering teams we work with understand that interconnects are not just accessories, they’re enablers of system performance. Whether you're launching a new product or solving a field problem, Meritec delivers solutions that address real-world constraints. Our FFC assemblies are trusted in high-reliability markets because we take the time to understand how your system works, and what could go wrong.

We don’t just sell a product. We help you build a better one.

The Smart Way to Route Signals in Compact Systems

As systems continue to shrink and performance requirements rise, flexible flat cable assemblies offer an ideal way to manage high-speed signals in limited space. They simplify internal layout, reduce material mass, and provide the signal integrity needed for modern data transmission.

Meritec’s FFC solutions combine smart materials, tailored engineering, and system-level support to deliver cables that aren’t just flexible—but fully functional in mission-critical environments.

Explore or Contact Us

Learn more about Meritec FFC assemblies:

https://www.meritec.com

Connect with Meritec engineers to start your design: