FROM CONCEPT TO CONNECTOR: HOW MERITEC DELIVERS CUSTOM CABLE ASSEMBLIES THAT PERFORM

Introduction: When Off-the-Shelf Isn’t Good Enough

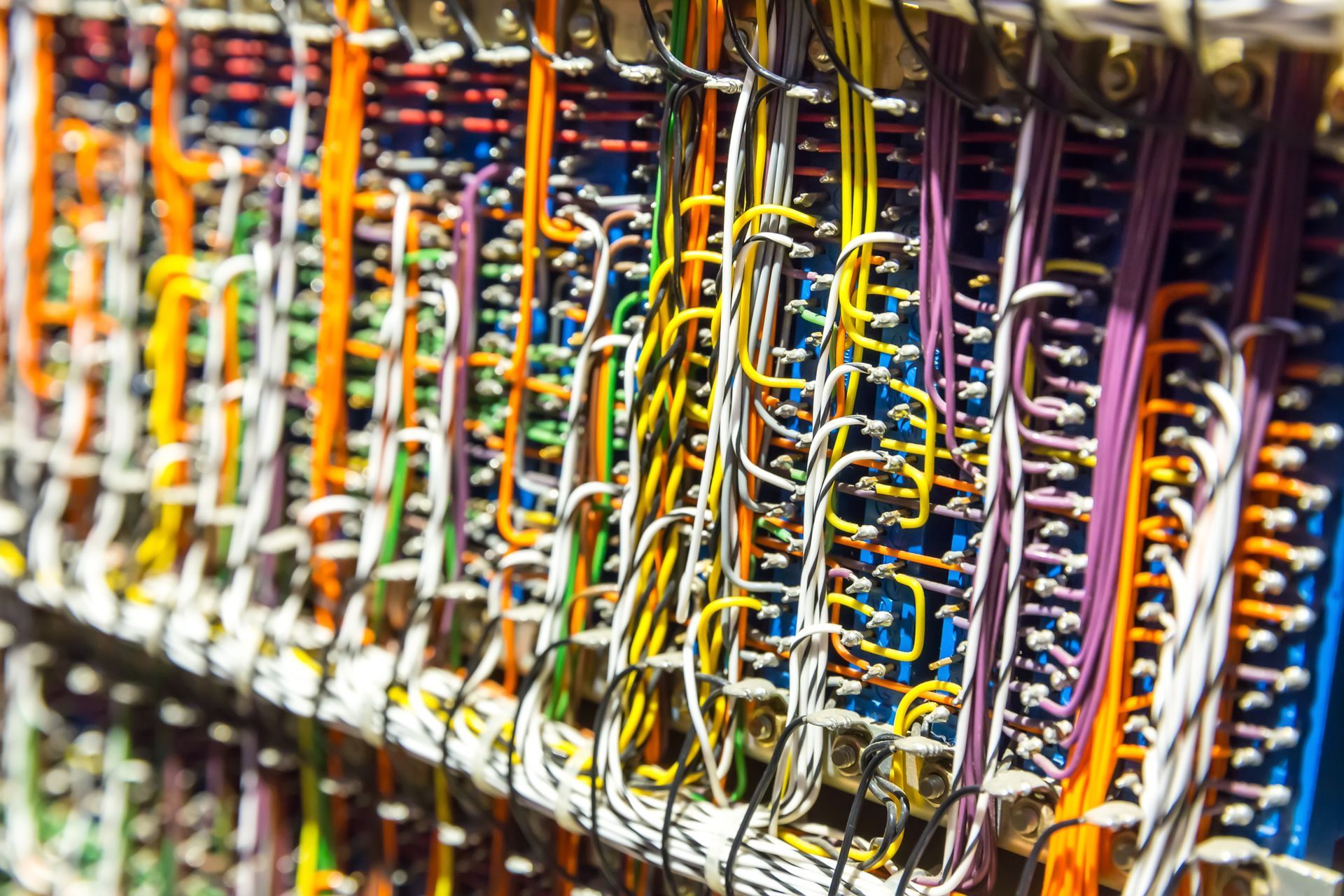

Some systems demand more than standard interconnects can provide. Whether it's a defense drone, an industrial robot, or a space-constrained medical device, engineers often face challenges that require cable assemblies built precisely for their environment, signal type, and mechanical requirements.

That’s where Meritec comes in. Our custom cable assemblies are not just modified products—they’re purpose-engineered solutions developed in close collaboration with system architects, project engineers, and integrators. From concept to production, we work hand-in-hand to ensure your cables don’t just fit—they perform.

Discovery and Application Engineering

The process begins with a conversation. What does the system need to do? What are the constraints? At this stage, Meritec engineers meet directly with your team to understand signal requirements, data protocols, temperature tolerances, mechanical motion, ingress protection levels, and routing paths.

We analyze the system topology, board locations, expected data rates, and EMI risks. The goal isn’t to find a "close match" off the shelf. It’s to define a cable assembly that is dimensionally optimized, electrically stable, and mechanically secure for its entire lifecycle.

Design Collaboration and Prototyping

Once requirements are clear, our engineering team develops CAD models, wiring schematics, and material stack-ups tailored to your specs. We factor in:

- Shielding design to reduce EMI

- Jacket materials for chemical, heat, or abrasion resistance

- Connector type (standard or custom) and orientation (right-angle, straight)

- Strain reliefs or overmolding for motion-intensive applications

- Hybrid layouts combining power and signal

Prototypes are built and delivered quickly for fit, form, and functional testing. We work closely with your lab team to validate electrical performance, mechanical routing, and installation clearances. If refinements are needed, we revise designs rapidly—with zero assumptions and full transparency.

Environmental & Electrical Testing

Meritec doesn’t stop at "good enough." We conduct comprehensive electrical and mechanical validation based on your system’s real-world demands. That includes:

- Impedance, insertion loss, and continuity verification

- Skew, jitter, and crosstalk testing for differential pairs

- Thermal cycling, shock, and vibration testing

- IP67 or IP68 ingress testing (if required)

All test data is documented and shared. We maintain traceability from raw cable to final assembly and build to IPC/WHMA-A-620 and MIL-STD standards.

Scalable Production with Engineering Oversight

Once the design is approved, we shift to production. Our in-house teams and validated partners can scale from small-volume builds to high-volume production with consistent quality. We use automated crimping, cutting, potting, and overmolding to maximize precision and reduce labor variance.

Each build undergoes inspection and validation. No two runs are treated the same without verification. That’s how Meritec maintains the reliability and performance expected in aerospace, defense, industrial, and high-speed computing platforms.

Real-World Example: Custom Harness for Military Vehicle Platform

One recent program involved retrofitting a digital control interface into a legacy ground vehicle. The system required a rugged cable that could route through tight bulkheads, resist vibration, support Gigabit Ethernet and USB, and withstand oil, salt spray, and thermal extremes. Meritec engineers designed a hybrid cable assembly using:

- 360° shielded twisted pairs for data

- Custom circular connector interface with keying

- Polyurethane jacket for chemical resistance

- Molded strain relief to prevent conductor fatigue

The assembly was tested under MIL-STD shock and vibration, EMI stress, and temperature cycling from -40°C to +85°C. It passed without performance loss and is now in full deployment.

Why Custom Makes Sense

Custom cable assemblies are not about complexity—they’re about control. Control over signal quality. Control over mechanical fit. Control over lifecycle reliability. In industries where failure is unacceptable, custom is often the simplest way to ensure success.

Meritec empowers engineers to design without compromise. We bring decades of experience, quick-turn prototyping, detailed engineering documentation, and production that matches your pace.

From a single prototype to fleet-wide deployment, our assemblies are built for the environments you design for—and the performance your end users demand.

Talk to Meritec. Build it Right From the Start.

Have a project that off-the-shelf solutions can’t support? Meritec is ready to help. Connect with our engineering team and start the process that leads from concept to high-performance connector.