HOW CABLE FLEXIBILITY AFFECTS ROBOTICS PERFORMANCE

Introduction: Flexibility Is Critical for Robotic Success

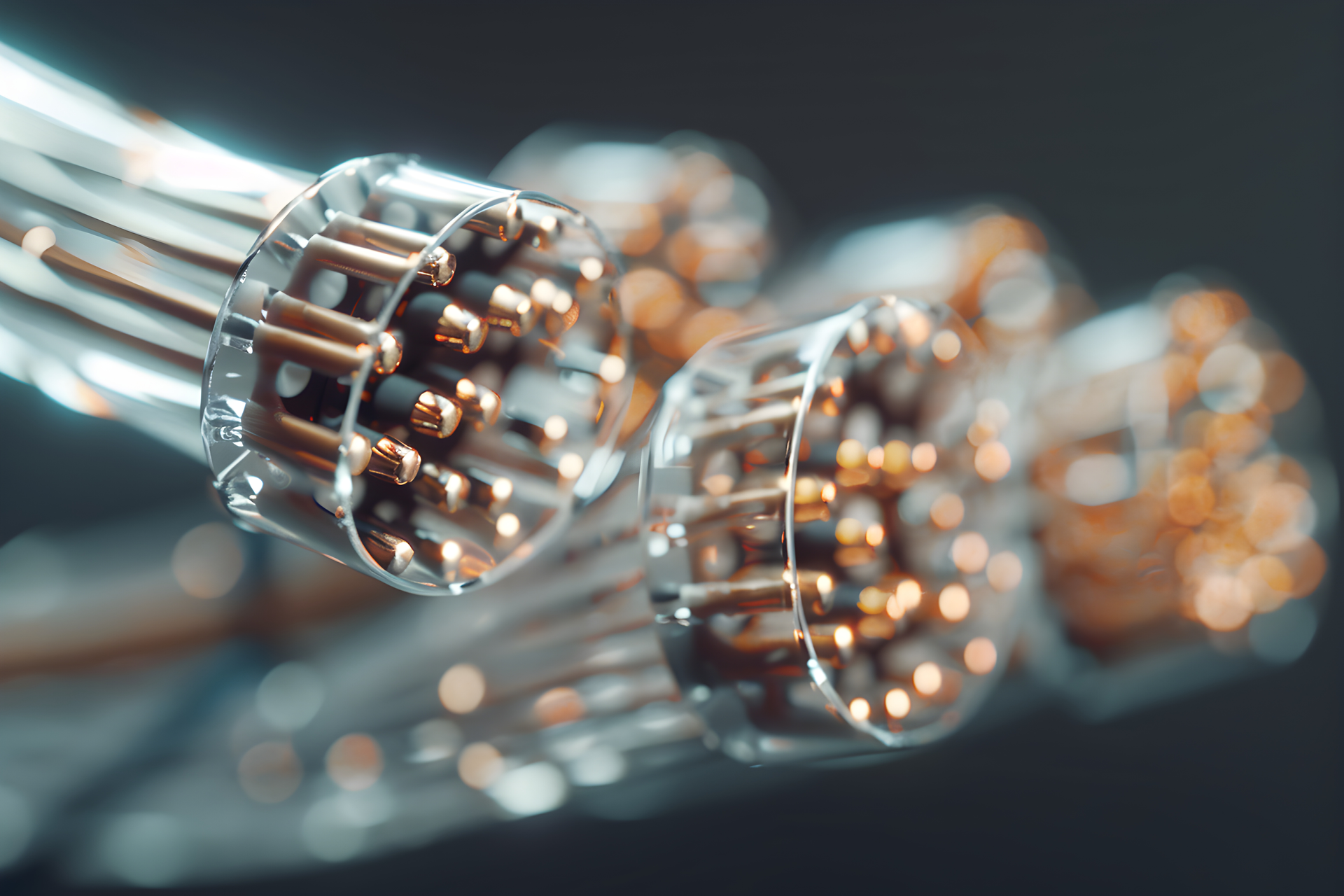

As robotics continues to evolve across industries from surgical devices and autonomous vehicles to industrial arms and collaborative robots cable flexibility has become a defining factor in system reliability and performance. Robotic systems are no longer static assemblies. Today’s applications demand movement, agility, and constant adaptability. In these environments, rigid or misaligned cables can become a source of signal loss, joint interference, or mechanical failure.

Meritec’s flexible cable assemblies for robotics

are designed to meet these challenges head-on. With advanced materials, tailored shielding, and robust form factors, Meritec enables high-speed, high-reliability interconnects in robotic systems of every scale and complexity.

The Link Between Cable Flexibility and Robotic Function

Cables in robotics serve as lifelines conveying data, power, and control signals to and from moving joints, sensors, vision systems, and end-effectors. Flexibility directly impacts:

- Kinematic Freedom: A highly flexible cable assembly allows robotic joints to move without introducing torque, drag, or resistance.

- Durability: Cables that flex repeatedly without degradation help extend mean time between failure (MTBF).

- Design Efficiency: Flexible cables allow for tighter routing, smaller bend radii, and lightweight cable paths key for mobile and compact systems.

Rigid or poorly matched cables, by contrast, can introduce mechanical fatigue, signal noise, and eventually failure. The bottom line:

the more dynamic the robot, the more crucial cable flexibility becomes.

Applications Where Flexibility Drives Performance

Different robotic categories place varying demands on interconnects:

| Application Segment | Motion Demands | Cable Flexibility Needs |

|---|---|---|

| Industrial arms | Continuous multi-axis articulation | Tight bending, resistance to torsion |

| Surgical robots | Ultra-precise, small-envelope movements | Micro-flex cable assemblies |

| Autonomous systems | Vibration, mobility, and environmental variation | Ruggedized, high-flex assemblies |

| Collaborative robots (cobots) | Frequent, safe motion near humans | Safe cable behavior, fatigue resistance |

Across each of these, Meritec provides

application-specific flexible cable solutions that balance movement, signal integrity, EMI shielding, and ruggedization.

Key Benefits of Flexible Cable Assemblies in Robotics

Here are the major ways flexibility enhances robotic system design:

1. Reduced Stress on Connectors and Joints

Every movement in a robotic system exerts force on the interconnect. Flexible cables minimize this stress, protecting critical termination points and reducing strain on board-mounted or edge connectors.

2. Improved Cable Lifespan Under Dynamic Conditions

Meritec’s flexible cable assemblies are designed and tested to withstand millions of flex cycles under simulated robotic motion. This includes:

- Bend radius testing

- Torsional cycling

- Abrasion and fatigue resistance

Such testing ensures consistent operation in continuous-use robotic systems.

3. Compact Routing and Tighter Designs

As robotics gets smaller and more mobile, flexible cables enable routing through narrow channels, hinges, or rotating arms. This allows for:

- Smaller cable bundles

- Lower profile harnesses

- Better airflow and mechanical freedom

4. Weight Reduction and Enhanced Mobility

Flexibility often goes hand-in-hand with lightweight cable construction. In aerial drones, mobile bots, or wearable robotics, this weight reduction improves maneuverability and reduces power draw.

Meritec’s Capabilities for Robotic Flex Cable Assemblies

Meritec supports a wide array of robotic needs through tailored engineering, prototyping, and production services:

- High-flex shielded twisted pairs

- Flat flex ribbon assemblies for planar routing

- Overmolded junctions for durability

- Miniaturized form factors for space-constrained robotics

- Hybrid signal/power routing in flexible cable bundles

These solutions are backed by decades of experience in

military, aerospace, industrial, and medical robotics, where failure is not an option.

Why Robotics OEMs Partner with Meritec

Robotics OEMs face mounting challenges from reducing footprint and weight to meeting strict compliance and life-cycle expectations. They choose Meritec because of:

- Application-Specific Design Support: Every robot is different. Our engineers work closely to meet system-specific bend radius, shielding, and connectivity needs.

- In-House Prototyping: We provide rapid turnarounds for custom interconnect development, including mating connectors and housings.

- Ruggedization for Harsh Use: Robotics doesn't always operate in clean labs. Meritec assemblies are built to survive dust, oil, chemicals, temperature shifts, and mechanical shock.

- Testing and Documentation: We offer full cable assembly validation including flex life, EMI compliance, and temperature cycling reports.

Designing for Flex: Factors to Consider

When specifying flexible cable assemblies, robotic engineers must consider:

Bend Radius

Specifying an improper bend radius is one of the most common design errors. Cables must support both static and dynamic bends based on their installed location and motion path.

Cable Construction

High-flex cable assemblies may use:

- Stranded conductors with fine gauge wire

- High-strength jackets such as polyurethane or TPE

- Shielded twisted pairs for noise rejection in signal cables

Environmental Exposure

Is your robot exposed to cleaning agents, extreme heat, or vibration? Each environment affects cable jacket choice, shielding, and connector sealing requirements.

Movement Profiles

Does the cable need to twist, rotate, or loop? Cable and strain relief design must match the actual movement path ideally modeled with CAD or physical mockups.

A Look at Common Flex Cable Types for Robotics

| Cable Type | Description | Robotic Use Case |

|---|---|---|

| Flat Ribbon Cable | Flexible, planar form; can fold in small enclosures | PCB-to-PCB flex in medical robots |

| Spiral Cables | Coiled for expansion/contraction | Extendable robot arms |

| High-Strand Round Cable | Multiple fine strands for extreme flexibility | Industrial arms, drones |

| Hybrid Cable Assemblies | Combine power, signal, data in one flexible jacket | Mobile robotics, AGVs |

Meritec engineers can help choose the ideal cable type or develop a fully custom option for your robotic system.

Conclusion: Flexible Cables Make or Break Robotic Performance

In robotic systems, cable flexibility is far more than a convenience it's a performance enabler. From movement efficiency to signal integrity, from durability to safety, every aspect of robot operation depends on the ability of interconnects to move with the system.

Meritec’s flexible cable assemblies for robotics

are engineered for these challenges. With decades of success in high-reliability environments, we’re trusted by robotic OEMs around the world to deliver cable assemblies that work again and again.

Build Your Robotic Interconnect System with Meritec

Flexible doesn’t mean fragile. Meritec designs high-flex, rugged cable systems that keep up with today’s most demanding robotic applications. Whether you’re designing for a surgical arm or a military crawler, our team is ready to help.