HOW TO SELECT THE RIGHT MIL-DTL-38999 CONNECTOR FOR YOUR APPLICATION

Introduction: More Than Just a Connector

In aerospace, defense, and rugged industrial systems, a connector is far more than a basic component. It is a vital part of the system’s performance and reliability. The MIL-DTL-38999 connector series stands as the gold standard for high-reliability circular connectors used across mission-critical applications. Whether in a fast-moving aircraft, military ground vehicle, or industrial robotics platform, selecting the right MIL-DTL-38999 connector directly impacts system integrity, environmental durability, and long-term serviceability.

At Meritec, we help engineers select and integrate MIL-DTL-38999-based interconnects that go beyond meeting specifications. Our Hercules® Interconnect System, for example, leverages MIL-DTL-38999 Series III shells while delivering high-speed performance that is engineered for modern protocols. In this guide, we share how to evaluate and select the ideal connector for your specific application.

Understanding the MIL-DTL-38999 Standard

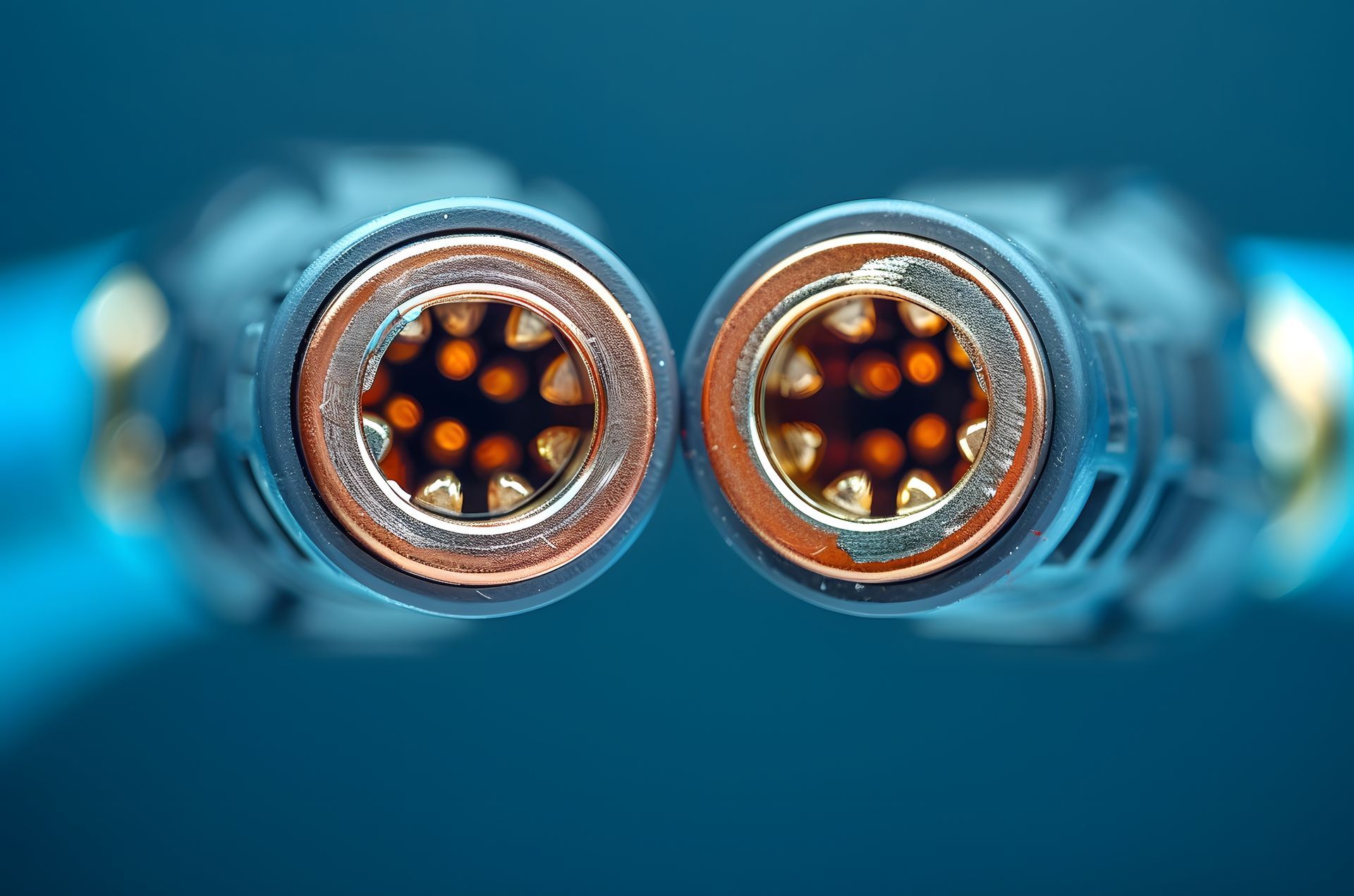

MIL-DTL-38999 connectors are high-density, threaded circular connectors originally developed for military aerospace applications. The standard defines the mechanical, electrical, and environmental performance of these connectors to ensure consistent interoperability.

There are four series under the MIL-DTL-38999 specification:

| Series | Key Features |

|---|---|

| Series I | Lightweight, bayonet coupling |

| Series II | Reduced size, bayonet coupling |

| Series III | High-vibration resistance, threaded coupling |

| Series IV | Self-locking, firewall-rated |

Series III is the most commonly used in rugged and high-reliability applications due to its mechanical robustness and EMI shielding capability. Meritec’s Hercules® system uses the Series III shell, providing a proven platform with additional high-speed design integration.

Key Factors to Consider When Selecting a MIL-DTL-38999 Connector

1. Mechanical and Environmental Performance

When selecting a connector for harsh environments, mechanical strength is paramount. Key considerations include:

- Vibration resistance: Vital in airborne and mobile systems.

- Shock tolerance: Needed for military and defense platforms.

- Ingress protection (IP rating): Important for exposure to dust and water.

- Temperature range: For example, Hercules® connectors operate from -65°C to +175°C.

- Material selection: Aluminum, stainless steel, or composite shells can affect weight and corrosion resistance.

Understanding your operating environment will help narrow the connector options.

2. Shell Size and Insert Arrangement

MIL-DTL-38999 connectors are available in various shell sizes, typically ranging from Size 9 to Size 25. The insert arrangement defines how many contacts and what type (signal, power, coax, or hybrid) will be present.

Choosing the correct shell size and insert layout ensures both electrical capability and mechanical fit within the system.

3. Electrical Performance and Protocol Compatibility

Modern systems often run high-speed digital protocols, requiring connectors to support signal integrity at elevated data rates. Look for:

- Impedance-matched differential pairs

- Low skew and jitter performance

- Support for protocols such as USB 3.x, PCIe, SATA, Ethernet, or HDMI

Meritec’s Hercules® assemblies use precision-engineered cables within the MIL-DTL-38999 shell to achieve clean high-speed performance up to and beyond 10 Gb/s per differential pair.

4. EMI Shielding and Grounding

In electrically noisy environments, EMI shielding is critical to preserving signal quality. MIL-DTL-38999 Series III shells naturally provide 360-degree EMI shielding when properly terminated.

Meritec enhances this with additional internal shielding and controlled impedance cable construction. Our design team ensures that your assembly meets both EMI requirements and overall system-level electromagnetic compatibility (EMC).

5. Mating Cycles and Maintenance

If your system will require frequent disassembly for maintenance or upgrades, connector durability is essential. MIL-DTL-38999 connectors offer long lifecycle mating ratings, but factors like contact plating, coupling mechanism, and material wear all influence longevity.

Our engineers help select configurations and materials that meet your usage expectations, minimizing the risk of premature wear in field service conditions.

6. Customization and Hybrid Layouts

Many applications require connectors that carry both power and data. Hybrid layouts can combine differential pairs, high-power contacts, RF coax, or even fiber optics within a single MIL-DTL-38999 connector.

Meritec offers modular Hercules® configurations to meet these needs, ensuring that your interconnect strategy supports both electrical and mechanical requirements without compromising performance.

Application Example: Aerospace Control Systems

A leading aerospace integrator required high-speed interconnects for a modular flight control system. The system operated in a high-vibration, high-altitude environment with temperature swings of over 150°C.

Meritec provided Hercules® assemblies built on MIL-DTL-38999 Series III shells, with:

- Precision low-skew differential pairs for 10 Gb Ethernet

- EMI shielding exceeding MIL-STD-461F standards

- IP67 sealing

- Locking features to prevent vibration-induced uncoupling

The result was a rugged interconnect solution that passed all flight qualification tests and is now deployed in active aircraft fleets.

Why Engineers Trust Meritec for MIL-DTL-38999 Solutions

Meritec’s engineering-first approach ensures that every connector assembly meets more than just spec—it meets your application’s full operational demands. From material selection to impedance modeling, thermal analysis to mechanical fit, our team delivers solutions that integrate seamlessly into aerospace, defense, robotics, and industrial platforms.

With Hercules®, we extend the capability of the MIL-DTL-38999 platform into the high-speed, high-reliability space that modern embedded systems demand.

Build the Right Connection for Your Mission

Selecting the right MIL-DTL-38999 connector means balancing rugged mechanical performance, precise electrical behavior, and application-specific customization. Meritec’s experience in designing and delivering MIL-compliant solutions helps ensure that your systems perform under the most demanding conditions—now and in the future.

Explore Hercules® high-speed rugged interconnect solutions: https://www.meritec.com

Speak with Meritec engineers to design the right MIL-DTL-38999 assembly for your project: https://www.meritec.com/contact