SFF-8470 CONNECTORS: THE STANDARD BEHIND HIGH-SPEED DATA TRANSFERS

Introduction: Signal Clarity in a High-Speed World

As systems continue to demand faster throughput, higher density, and lower latency, the quality of the signal path becomes just as important as the data itself. In applications like radar systems, embedded computing, and test labs, connector performance can make or break functionality.

At Meritec, we’ve engineered our SFF-8470 (NX) cable assemblies to perform in rugged environments where signal integrity is non-negotiable. These connectors offer high-speed performance, superior EMI protection, and physical durability, all in a compact form factor. Whether you're transmitting PCIe, Serial RapidIO, or 10G Ethernet, our solutions are purpose-built to meet your speed and shielding requirements.

Understanding the SFF-8470 Standard

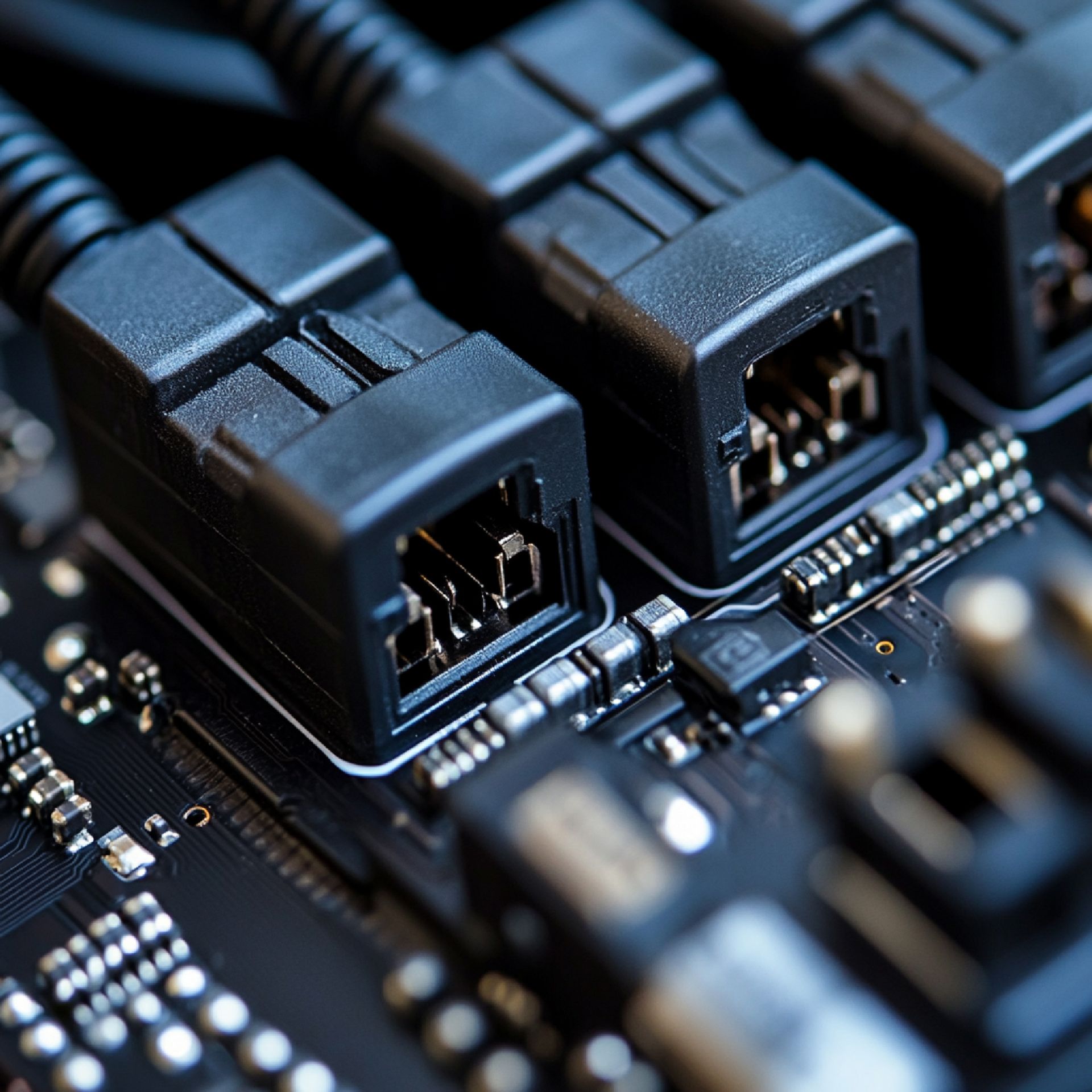

The SFF-8470 (Small Form Factor) standard was originally designed to support storage and I/O protocols, but it has become a trusted connector platform for modern high-speed interconnects. The standard defines a multi-lane connector that accommodates up to four differential signal pairs, each capable of transmitting 10 Gb/s or more, depending on the cable quality and system environment.

Beyond raw performance, the standard’s appeal lies in its mechanical stability and adaptability to multiple protocols, including PCI Express, SAS, InfiniBand, and 10G Ethernet. Its compact interface allows it to be used in high-density systems without compromising on speed or durability.

What sets SFF-8470 apart is its ability to maintain high-frequency signal integrity while enduring real-world stressors such as temperature cycling, vibration, and electromagnetic interference. That’s why this connector form factor is a staple in industries that demand speed and consistency in rugged environments.

How Meritec Improves on the Standard

The first priority in rugged connector design is choosing materials that can perform under pressure. That means shells built from aircraft-grade aluminum, stainless steel, or composite alloys, often plated for corrosion resistance. Internally, contact systems are designed to maintain low resistance and high cycle life.

The connector geometry also plays a critical role. Meritec offers both straight and right-angle options to fit into compact enclosures and tight layouts. These connectors feature mechanical locking system, such as bayonet or threaded couplings, to prevent accidental disconnection under vibration or impact.

Cables used in ruggedized I/O assemblies are equally important. They must offer abrasion resistance, flexibility under repeated motion, and support high-speed signal transmission. Jackets are selected based on the environment, polyurethane or Teflon® for chemical resistance, FEP or silicone for thermal resilience.

Designed for Harsh Applications and Real-World Performance

Our connectors are trusted in environments where both performance and reliability are mission-critical. Take, for example, a recent aerospace project that required high-speed sensor data to travel from the wing-mounted hardware to a processing unit inside the fuselage. The solution had to be EMI-resistant, vibration-stable, and compact enough to fit within a sealed housing. Meritec’s SFF-8470 (NX) assembly delivered exactly that, high bandwidth, clean signals, and field-proven ruggedness.

In defense environments, our assemblies are used in battlefield communications systems where electromagnetic shielding is a necessity. In telecom, they support high-frequency backplane links and edge routing systems. In industrial automation, our cable assemblies provide low-latency control paths between intelligent equipment, even in environments subject to shock, temperature extremes, and radio-frequency interference.

From Prototype to Production: Designed with You in Mind

We understand that engineering teams are under pressure to deliver high-speed designs that are both robust and adaptable. That’s why our approach is collaborative. We don’t just ship cables, we partner with your engineers to understand your system architecture, environmental conditions, signal protocols, and mechanical constraints.

Our SFF-8470 (NX) assemblies are available in both straight and right-angle configurations. Cable lengths, jacket materials, shielding levels, and retention hardware can all be specified during the design phase. Whether you're in early prototyping or refining a production layout, we provide everything from 3D CAD models and datasheets to short-turn custom builds for test platforms.

This hands-on engineering support streamlines development, minimizes rework, and ensures your interconnect system integrates seamlessly.

Performance Backed by Testing and Compliance

Meritec’s SFF-8470 (NX) assemblies are tested under real-world conditions. Each product is manufactured under IPC/WHMA-A-620 Class II and III standards and validated for signal performance under thermal, mechanical, and EMI stress.

Our internal lab testing process evaluates impedance control, insertion loss, return loss, shielding effectiveness, and contact durability. The assemblies undergo environmental chamber testing for thermal cycling, vibration profiles, and humidity resilience, particularly important in defense and aerospace installations.

We also ensure mating cycle longevity, so your connectors won’t degrade after repeated maintenance or module swaps.

By going beyond just "meeting spec" and actually validating product performance at the system level, we deliver not just connectors, but confidence.

Why Engineers Trust Meritec for High-Speed Connectivity

Meritec has been a trusted interconnect partner for decades, providing solutions to aerospace primes, Tier-1 defense integrators, advanced robotics firms, and telecom leaders. Our success comes from combining real engineering knowledge with proven manufacturing expertise.

When you specify an SFF-8470 (NX) connector from Meritec, you're choosing more than signal speed. You’re choosing EMI suppression that holds up under stress. You're selecting mechanical designs that survive deployment. And you're backed by a team that understands your build schedule, your protocol demands, and your system constraints.

Proven in the Field, Ready for What’s Next

Our rugged I/O connectors are trusted in applications ranging from ground vehicles and aircraft to drilling rigs and automated manufacturing cells. We provide fast-turn prototyping, complete electrical and mechanical documentation, and full support through design verification and production.

Engineers choose Meritec because we don’t just sell connectors, we solve interconnect challenges in high-stakes environments. Our products are backed by testing, documentation, and real-world validation to ensure that once they’re deployed, they stay connected.

Customize Your Interconnect with Meritec

If you’re building high-speed systems that demand more than just basic functionality, systems that operate in the air, on the ground, or in noisy, industrial settings, Meritec’s SFF-8470 (NX) solutions are built for that purpose.

Let us help you design a connector system that meets your exact performance, compliance, and integration needs. From rapid prototypes to volume production, we’re here to ensure your high-speed interface performs reliably every time.

Explore or Contact Us

Learn more about Meritec’s board-to-board interconnect solutions:

Speak directly with our engineers about your embedded design: