CUSTOM CABLE ASSEMBLIES FOR AUTONOMOUS VEHICLE SYSTEMS

The rapid advancement of autonomous vehicle technology is transforming how we move, deliver, defend, and explore. From driverless cars and unmanned delivery fleets to robotic mining equipment and military drones, autonomy depends on fast, rugged, and reliable interconnects. At the core of this evolution are custom cable assemblies engineered specifically to meet the electrical, mechanical, and environmental challenges of autonomous systems.

This article explores the essential role of custom cable assemblies in autonomous platforms, the engineering that ensures performance in extreme conditions, and how Meritec helps manufacturers bring their concepts to reality.

Why Autonomous Systems Demand Custom Interconnects

Autonomous platforms require a complex network of components working in unison sensors, control modules, imaging devices, processors, actuators, and external communication systems. These systems transmit enormous volumes of data in real-time. Inconsistent performance, EMI interference, or physical degradation can lead to failure, and in critical applications, that failure could be catastrophic.

Custom cable assemblies are designed to:

- Transmit data at high speeds across multiple protocols

- Maintain signal integrity in high-EMI environments

- Withstand shock, vibration, and temperature fluctuations

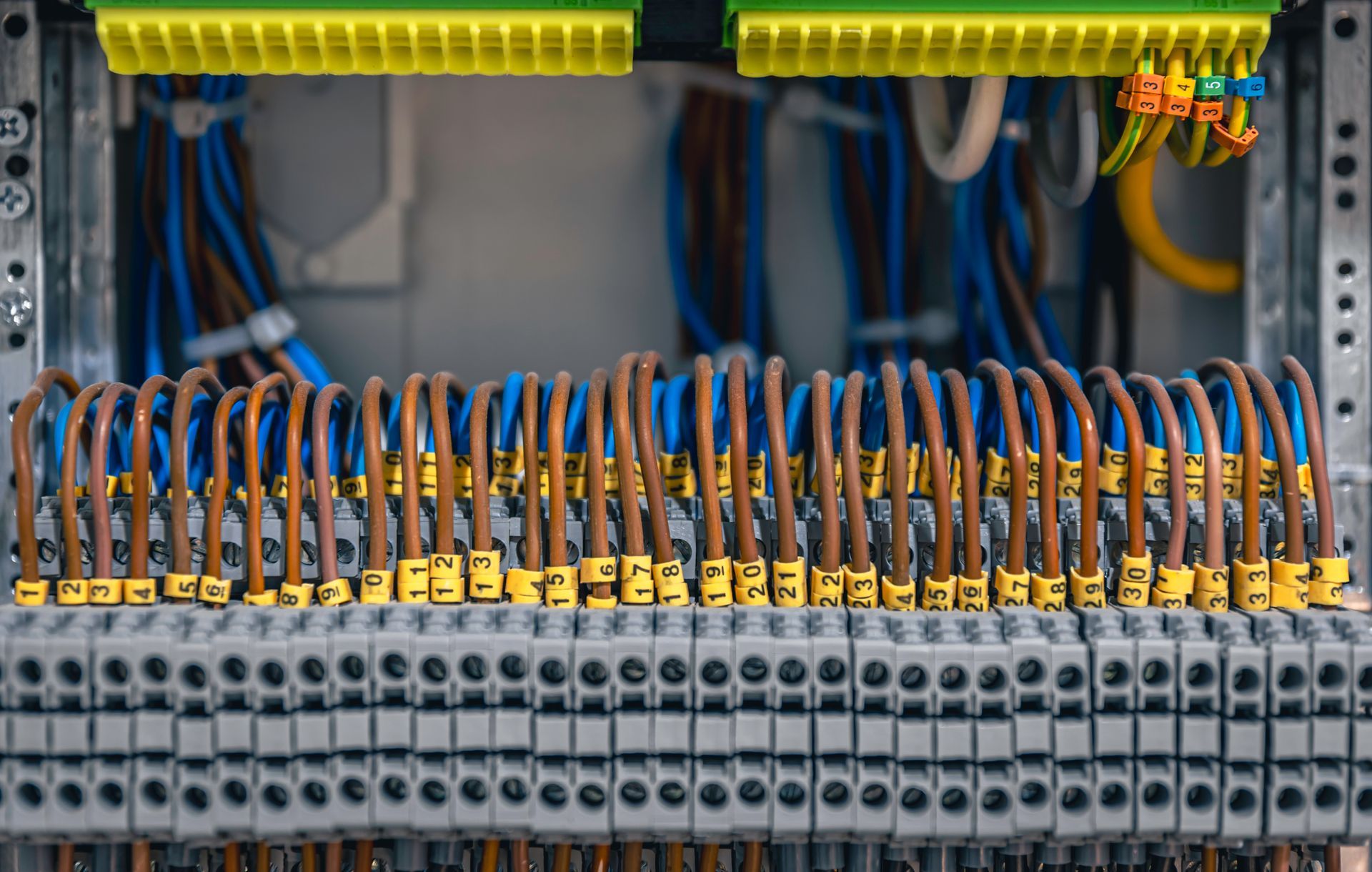

- Fit precisely into confined, dense electronics housings

- Enable hybrid signal integration (power, RF, fiber, data)

Off-the-shelf cables rarely offer this level of precision or durability. For autonomous systems to perform consistently and safely, interconnects must be custom-designed with their exact application and environment in mind.

Navigating Harsh Environments with Confidence

Environmental challenges are one of the defining characteristics of autonomous platforms. Self-driving vehicles operate in urban, rural, and off-road conditions. Military robots encounter dust, water ingress, corrosive agents, and battlefield shocks. Delivery drones experience rapid altitude changes, high vibration, and UV exposure.

To operate in these scenarios, cable assemblies must incorporate:

- Abrasion-resistant jackets made from TPE, PUR, or PTFE

- Sealed and overmolded connectors that prevent moisture and particle ingress

- Braided, foil, or layered shielding to block EMI

- Strain relief and bundling techniques to reduce flex-related failure

- Temperature-rated materials that maintain integrity in extreme cold or heat

These features protect both signal quality and the mechanical structure of the cable, ensuring performance doesn't degrade over time.

Engineering for Application-Specific Demands

Customization isn’t limited to environmental factors. It also ensures compatibility with unique electrical, spatial, and mechanical constraints.

A few examples:

- Vehicle Imaging Systems require compact, flexible cables that don’t interfere with camera fields of view, while still supporting high-speed data transmission via LVDS or USB 3.0.

- Defense Robotics may need MIL-STD compliance, support for RF systems, and braided shielding for enhanced EMI protection.

- Industrial Autonomy solutions might demand high-pin-count connectors and hybrid assemblies capable of carrying power, CAN bus, and Ethernet.

Meritec collaborates with engineering teams from early design stages to understand the platform’s purpose, space limitations, and performance targets. This allows us to specify materials, choose the ideal connector interface, and design the cable geometry to exact system needs.

The Data Protocol Landscape in Autonomous Platforms

Autonomous systems utilize multiple communication standards. Each protocol presents different design challenges.

| Protocol | Primary Use | Design Implication |

|---|---|---|

| Ethernet (100/1000Base-T1) | High-speed system communication | Controlled impedance, shielding critical |

| CAN Bus | Vehicle control and diagnostics | Low-latency, reliable across vehicle length |

| USB 3.x | Camera, sensors, data logging | High-frequency support, compact form |

| LVDS | High-resolution video feeds | Minimal skew, signal pairing consistency |

| RF/Coax | GPS, radar, telemetry | EMI shielding, precise connector mating |

| Fiber Optics | EMI-immune high bandwidth | Termination precision, bend radius control |

Designing a cable assembly for multiple protocols often means hybridizing signal types within a single bundle, minimizing total system weight and reducing installation complexity.

Regulatory and Safety Requirements

Safety and compliance are essential to widespread deployment and adoption. This includes both industry-specific regulations and broader standards of quality.

Custom assemblies often support:

- ISO 26262 functional safety for automotive systems

- UN ECE R10 EMC compliance

- MIL-STD environmental testing for defense applications

- UL, RoHS, and REACH material certifications

Meeting these standards requires validated manufacturing processes, traceability, and comprehensive testing.

Meritec performs electrical, mechanical, and environmental validation testing on every custom assembly including:

- Thermal cycling

- Vibration and shock

- Continuity and impedance testing

- High-pot and insulation resistance

The Value of Design Flexibility and Support

Custom cable development doesn’t have to be slow or cost-prohibitive. Meritec’s design process is rooted in collaboration. Our engineers provide early-stage guidance on:

- Connector selection and pinout configuration

- Jacket and shielding materials

- Assembly routing and flexibility targets

- Integration with enclosures and PCB headers

We offer quick-turn prototyping, short-run production, and full-scale ramp-up all under one roof. Whether your system is in concept or field-testing stages, we adapt to your timeline and support evolving specs.

Emerging Design Trends in Autonomy

As the autonomous vehicle space grows, several trends are influencing interconnect development:

- Miniaturization – Electronics are shrinking, and interconnects must follow suit with tighter bend radii and smaller connectors.

- Hybridization – Combining power, control, RF, and fiber in a single cable improves space efficiency and reduces complexity.

- Modularization – Plug-and-play harnesses simplify serviceability and manufacturing.

- Resilient materials – Cables must resist fuel exposure, chemicals, abrasion, and extreme weather.

- Digital twins – Simulating cable routing and behavior helps avoid integration surprises.

Meritec stays ahead of these trends through ongoing R&D, material sourcing, and investment in next-generation tooling.

Partnering With Meritec for Autonomous Cable Assemblies

Meritec has long served industries that depend on rugged, mission-critical interconnects. Our experience in defense, aerospace, industrial automation, and high-speed data systems translates directly to autonomous platforms.

Whether your project requires:

- Low-profile imaging harnesses

- Hybrid RF/power/data cables

- High-flex robotics assemblies

- MIL-compliant shielded solutions

Meritec provides proven performance, collaborative engineering, and end-to-end manufacturing quality. Our solutions are built for harsh environments and designed to evolve with your platform’s future demands.

FAQ: Custom Cable Assemblies for Autonomous Vehicle Systems

What makes a cable assembly suitable for autonomous vehicles?

A suitable assembly supports high-speed, low-latency communication while maintaining durability in extreme environments. It must be engineered to meet protocol, shielding, and flexibility needs specific to the application.

Can standard off-the-shelf cables be used in autonomous platforms?

In most cases, no. Autonomous systems require cable assemblies that match exact routing paths, shield against EMI, and meet regulatory requirements. Off-the-shelf solutions often lack this precision.

What protocols are commonly used in autonomous vehicle cable assemblies?

Common protocols include Ethernet, CAN bus, USB, LVDS, RF/coax, and fiber optics. Assemblies may combine multiple protocols in one hybrid solution.

How does Meritec validate reliability and compliance?

Meritec conducts mechanical, electrical, and environmental testing to verify compliance with ISO, MIL, and EMC standards. All assemblies are inspected and validated before delivery