HIGH-SPEED DATA TRANSMISSION IN DEFENSE VEHICLES: KEY INTERCONNECT CHALLENGES

As defense vehicles evolve into digital command centers on wheels, the need for high speed data transmission is no longer a luxury it's a mission-critical requirement. From real-time targeting and threat detection to onboard AI systems and network-centric warfare, modern military platforms rely on a dense web of sensors, processors, and communication modules. At the heart of these systems lie rugged, high-performance cable assemblies that must maintain speed, reliability, and integrity under the most extreme operating conditions.

This article explores the core interconnect challenges that arise when implementing high speed data transmission in defense vehicles and how advanced cable assemblies can overcome these obstacles. With decades of experience in the defense sector, Meritec designs and manufactures interconnect solutions engineered to meet the stringent performance demands of today's battlefield environments.

The Growing Bandwidth Demands in Military Platforms

Data consumption in military ground vehicles has surged due to several technological shifts. Systems such as high-definition video surveillance, radar imaging, sensor fusion, electronic warfare, and real-time vehicle-to-vehicle (V2V) and vehicle-to-command communication demand greater bandwidth than ever before.

Unlike commercial applications, where high-speed data transmission can rely on relatively stable environments, defense vehicles must transmit mission-critical data through a maze of electromagnetic interference (EMI), temperature extremes, vibration, and physical abuse. This places unique demands on interconnect systems that support high-speed digital protocols such as 10G Ethernet, USB 3.x, HDMI, PCIe, and custom high-speed signaling.

Meritec's defense vehicle high-speed cable assemblies are engineered for these challenges, ensuring reliable throughput regardless of the platform's mobility or environment.

Environmental and Mechanical Stressors

Defense vehicles operate in harsh and unpredictable conditions, including deserts, arctic tundra, wet jungles, and urban conflict zones. The interconnects within these systems must survive thermal cycling from -55°C to +125°C, constant shock and vibration from uneven terrain, exposure to water, fuel, dust, and potentially corrosive decontaminants.

Conventional cable systems often fail in these conditions, leading to signal loss, intermittent faults, or total system failures. To ensure long-term reliability, Meritec incorporates a combination of shielding, overmolding, strain relief, and specialized jacket materials into its defense-grade cable assemblies. This design approach not only protects the electrical performance but also extends operational life under battlefield conditions.

EMI and Crosstalk Mitigation

One of the most significant technical hurdles in transmitting high-speed data in defense vehicles is managing electromagnetic interference. Multiple subsystems—including radar, communication arrays, and power electronics—emit high levels of EMI. Without proper shielding and layout, high-speed data signals can become corrupted by noise or induce interference in adjacent systems.

Meritec addresses this challenge with assemblies that feature precision-terminated shielding, multi-layer foil and braid designs, and strict impedance control. Connectors are selected or custom-engineered for optimal signal integrity, and cable routing is designed to minimize crosstalk. This careful engineering ensures that data signals maintain fidelity even when operating adjacent to noisy power or RF systems.

Signal Integrity Over Distance

While some defense platforms use distributed computing to minimize internal data transmission distances, many vehicle applications still require high-speed links spanning several feet or more. Maintaining signal integrity over these longer distances in a noisy environment requires cable assemblies with matched impedance, low insertion loss, and robust shielding.

Meritec uses advanced simulation tools to design assemblies that perform reliably across extended distances and varying frequencies. Precision-controlled impedance and high-quality dielectric materials reduce signal degradation, enabling sustained operation at data rates exceeding 10 Gbps.

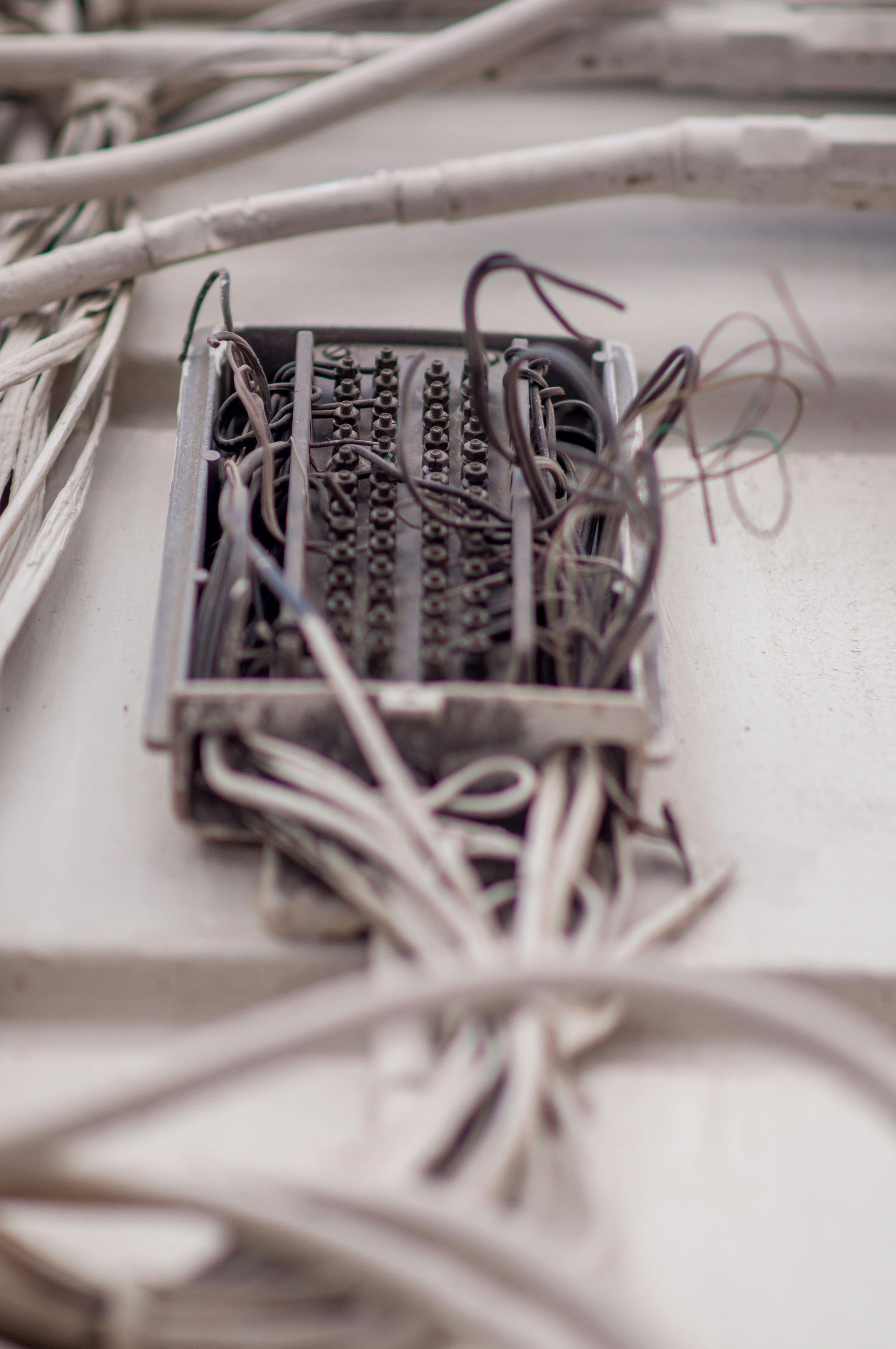

Connector Reliability and Mechanical Integrity

The connectors used in defense vehicle cable assemblies are subject to repeated mating cycles, vibration, and physical handling during maintenance or upgrade operations. A failed or loose connector can compromise the entire system. As a result, connector selection and integration become pivotal to the success of the interconnect design.

Meritec offers a range of MIL-spec and custom connectors, including those compliant with MIL-DTL-38999, VITA 67, and Nano-D standards. These connectors feature anti-decoupling mechanisms, positive locking, and environmental seals to prevent ingress of contaminants. Meritec also customizes mating interfaces to meet platform-specific form factors or space constraints without sacrificing durability or performance.

Space and Weight Constraints

Defense vehicles are becoming more compact while packing more computing and sensing capabilities. This puts pressure on designers to reduce size, weight, and power (SWaP) across all components, including cable assemblies. Bulky interconnects can block airflow, interfere with moving parts, or add unnecessary mass to already weight-sensitive platforms.

To address SWaP challenges, Meritec designs lightweight, low-profile assemblies using micro-coaxial cables, thin wall insulation, and high-density connectors. These solutions not only reduce weight but also allow tighter cable routing, which is critical in vehicles with confined electronics bays or modular component racks.

Ruggedization Techniques

To withstand the extreme mechanical and environmental conditions of defense operations, cable assemblies must undergo extensive ruggedization. Meritec's assemblies include features such as:

- Overmolded strain reliefs to prevent conductor fatigue

- EMI shielding layers to block interference from internal and external sources

- High-flex life conductors and jackets for dynamic motion

- IP67/IP68 sealing for liquid and particulate ingress protection

- Flame-retardant and chemical-resistant materials for safety and durability

These ruggedization methods are tested to MIL-STD-810 and other defense-relevant standards to validate real-world performance.

Comparison Table: Commercial vs. Defense Cable Assembly Requirements

| Attribute | Commercial Applications | Defense Vehicle Applications |

|---|---|---|

| Operating Temperature | 0°C to +70°C | -55°C to +125°C |

| EMI Exposure | Moderate | High (adjacent to RF/Power) |

| Connector Type | Consumer/Industry Grade | MIL-Spec or Custom Rugged |

| Shielding | Basic Foil or None | Multi-layer EMI + Braid |

| Environmental Sealing | Limited | IP67/IP68 Rated |

| Flexibility Requirements | Low | High (dynamic flex and vibration) |

| Compliance Standards | CE, RoHS | MIL-STD-810, MIL-STD-461 |

This table illustrates why off-the-shelf commercial cable systems often fail in military platforms and highlights the necessity of defense-specific interconnect designs.

Testing and Validation

All Meritec defense vehicle high-speed cable assemblies are subject to rigorous qualification and verification testing. These include:

- Signal integrity testing using time-domain reflectometry (TDR) and vector network analyzers (VNA)

- EMI and EMC testing to ensure system compatibility

- Environmental stress tests including thermal cycling, fluid exposure, and vibration endurance

- Connector retention and durability validation

This level of scrutiny ensures that every assembly functions correctly not only in lab conditions but also in operational theaters where failure is not an option.

Application Scenarios in Modern Defense Vehicles

High-speed cable assemblies are critical across a variety of onboard systems. Applications include:

- Real-time sensor fusion between LIDAR, radar, and infrared arrays

- Networked battlefield management systems requiring secure data exchange

- High-resolution situational awareness and targeting video feeds

- Encrypted communication between vehicle and command centers

- Data links to edge AI processors and mission computers

Each of these applications requires rapid, secure, and uninterrupted data transfer that cannot be compromised by environmental or mechanical stressors. Meritec ensures every interconnect supports these mission objectives.

Future Considerations and Evolving Demands

As military systems evolve toward more autonomous functions, software-defined networking, and hybrid electric drivetrains, data throughput and interconnect reliability will become even more critical. Cable assemblies must support higher frequencies, smaller geometries, and tighter mechanical constraints without sacrificing ruggedness.

Meritec continues to innovate by developing new materials, connector formats, and signal optimization techniques to stay ahead of these evolving requirements. Collaborations with defense OEMs during early design stages allow Meritec to tailor solutions that address platform-specific SWaP goals, thermal envelopes, and electromagnetic environments.

Partnering with Meritec

For defense OEMs, integrators, and platform designers seeking robust solutions for high-speed data connectivity, Meritec provides a trusted partner with deep domain expertise. From initial consultation through prototyping and production, Meritec engineers deliver defense vehicle high-speed cable assemblies that meet the most demanding standards of performance, reliability, and environmental resistance.

Explore Meritec's full suite of defense-grade interconnects and start designing a high-speed system that performs where failure is not an option.