MICRO COAXIAL VS. RIBBON CABLE: WHICH FITS COMPACT HIGH-SPEED DESIGNS?

As high speed electronic systems become increasingly compact, engineers face difficult choices in selecting the right cable architecture. Two leading contenders for space-constrained, high data rate environments are

micro coaxial cables and

ribbon cables. While both can carry signals reliably, they differ significantly in construction, performance, and application suitability. Understanding these distinctions is critical for making the right selection in high-density designs.

Understanding Micro Coaxial Cable Construction

Micro coaxial cables consist of individual coaxial conductors each with a center conductor, dielectric insulator, shielding layer, and outer jacket bundled together in a flat or round profile. Their shielding effectiveness and impedance consistency make them well suited for high-speed differential signaling, even at GHz frequencies.

Key characteristics of micro coax cables include:

- Excellent signal integrity due to coaxial construction

- High shielding performance against EMI/RFI

- Precision impedance control (typically 50 or 75 ohms)

- Support for differential or single-ended signaling

Micro coax cables are often terminated with ultra-fine pitch connectors, making them ideal for applications where signal performance cannot be compromised.

Overview of Ribbon Cable Architecture

Ribbon cables consist of parallel, insulated conductors bonded together in a flat planar format. These cables excel in ease of mass termination and routing within systems. Commonly used in internal interconnects such as board-to-board or module-to-module connections, ribbon cables can be manufactured using discrete wires or flexible printed circuits (FPCs).

Advantages of ribbon cable assemblies include:

- Space-efficient flat geometry for tight systems

- Simplified assembly using mass termination connectors

- Lower material cost and simplified manufacturing

- Flexible customization for pitch and conductor count

While ribbon cables can support relatively high speeds, they may require careful design and shielding techniques to avoid cross-talk and maintain signal fidelity.

Performance Comparison in High-Speed Compact Systems

When evaluating these two cable types for high-density electronic environments, several key performance dimensions must be considered

Table: Comparison of Micro Coaxial vs. Ribbon Cables

| Feature | Micro Coaxial Cable | Ribbon Cable |

|---|---|---|

| Signal Integrity | Superior; minimal crosstalk | Moderate; depends on layout & shielding |

| EMI/RFI Shielding | Excellent (individual shielding per line) | Limited unless external shielding is added |

| Impedance Control | Tight tolerance (ideal for GHz rates) | Variable; depends on geometry and materials |

| Flexibility | Moderate; can be routed in tight spaces | High; ideal for flat/linear runs |

| Termination Options | Fine-pitch, high-density connectors | Mass termination with IDCs/FPCs |

| Space Efficiency | High, with precise routing | Very high in planar applications |

| Durability | High in rugged environments | Moderate; less robust against flex/fatigue |

| Cost | Higher due to construction complexity | Lower material and production cost |

Use Cases for Micro Coaxial Cables

Micro coaxial assemblies are increasingly used in environments where electromagnetic performance is critical. Examples include:

- Medical imaging systems: High-resolution signal paths for ultrasound and endoscopy

- Aerospace avionics: Ruggedized connections with low phase distortion

- RF and mmWave test equipment: Consistent impedance and shielding

- Embedded vision systems: Camera-to-processor links with low jitter and skew

Their ability to support extremely high data rates up to 20+ Gbps in some designs while maintaining tight control of signal paths makes micro coax the default choice when performance is prioritized over cost.

Use Cases for Ribbon Cables in Compact Designs

Ribbon cables remain popular for internal system wiring where cost, assembly speed, and layout flexibility matter more than ultra-high signal performance. Common applications include:

- Consumer electronics: Internal links between display, logic board, and battery module

- Office equipment: Parallel data transmission within printers, scanners, and copiers

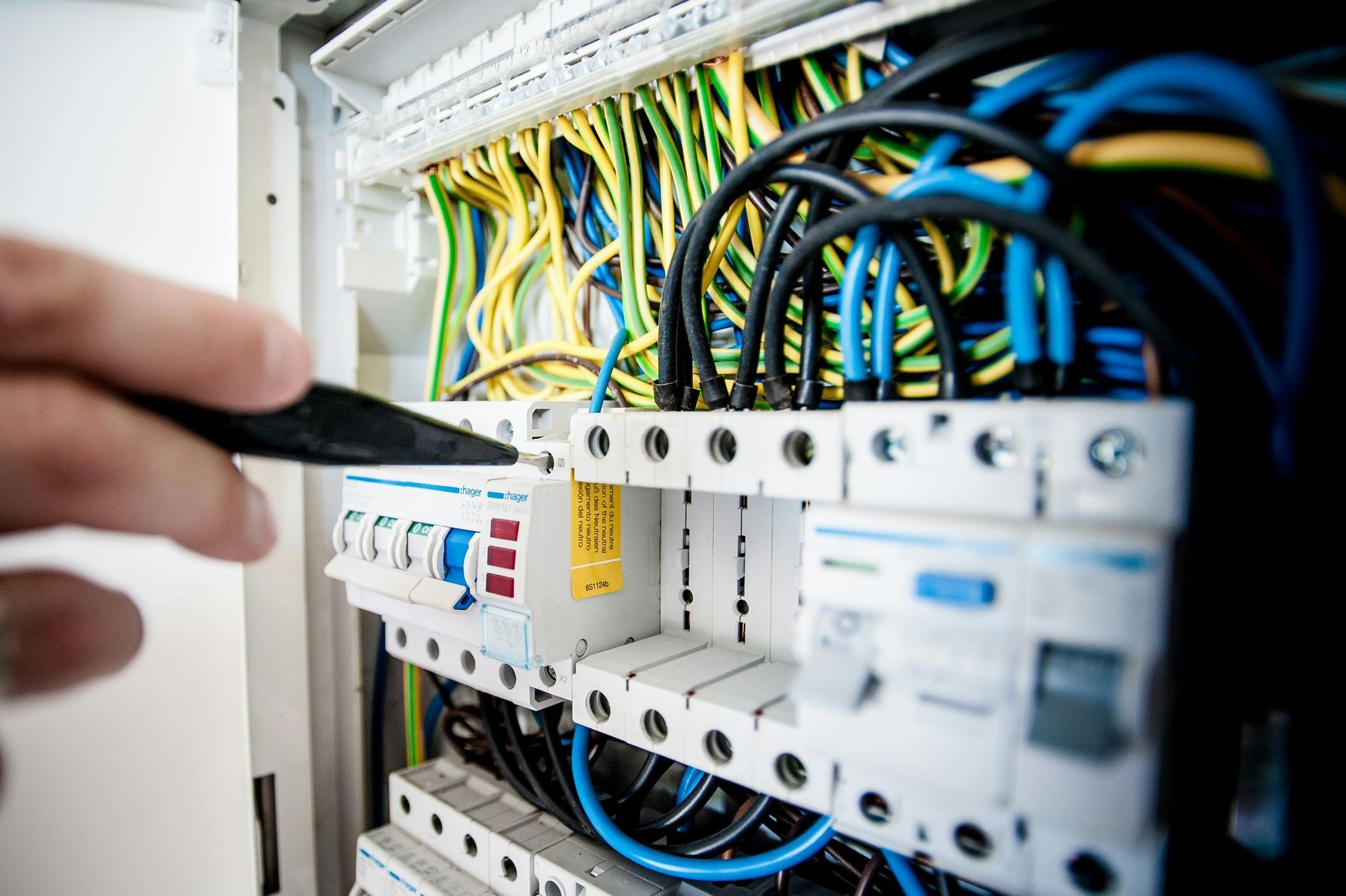

- Industrial controls: Short-distance connections within control panels or enclosures

- Automotive infotainment: Flat cable paths behind dashboards or displays

While not optimized for extremely high-frequency applications, ribbon cables can be engineered with shielding or differential pairs to meet mid-speed digital requirements (e.g., USB 2.0, LVDS, SPI).

Meritec’s Solutions for Signal Integrity Challenges

Meritec specializes in

high-speed embedded interconnect solutions for demanding environments. Our product portfolio includes:

- Rugged cable assemblies designed for signal integrity across extended temperatures and vibrations.

- Custom impedance matched connectors to reduce reflections.

- Overmolded strain relief assemblies that maintain shielding and prevent cable ingress.

- Hybrid interconnects combining power, signal, and RF with isolated paths.

These systems are extensively tested using signal integrity validation tools including eye diagrams, TDR, and EMI scanning.

Key Selection Factors for Engineers

Choosing between micro coax and ribbon cable assemblies requires a close look at system requirements. Engineers should ask:

- What is the target data rate? Applications above 5 Gbps typically favor micro coax.

- How critical is shielding and EMI control? Environments with noisy power systems or RF exposure demand better shielding.

- Is the space available planar or irregular? Ribbon cables are better for straight-line runs; micro coax excels in complex routing.

- What are the durability needs? For repeated flex or high-cycle mating, micro coax with ruggedization options will last longer.

- What are the cost constraints? Ribbon may be more economical for moderate-speed, short-run links.

Engineers often find that micro coax offers a performance edge, especially in mission-critical systems, while ribbon cable delivers flexibility and speed-to-market in volume production environments.

Emerging Trends and Hybrid Approaches

Recent innovations are beginning to blur the lines between these two technologies. Hybrid cable assemblies combining ribbon geometry with coaxial construction are being developed to meet unique performance and form-factor needs. Additionally, flexible micro coax ribbon arrays allow for multi-channel high-speed transmission in planar form, bridging a key gap in traditional designs.

Some manufacturers also offer shielded ribbon cables with embedded ground planes and staggered conductor layouts to reduce crosstalk and support multi Gbps signaling. These innovations are helping ribbon style cables find new relevance in higher-speed designs previously dominated by micro coax.

Meritec’s Expertise in Compact High-Speed Cable Assemblies

At Meritec, we specialize in both micro coax and advanced ribbon-style interconnect solutions for demanding compact applications. Whether your project requires precision micro coax for rugged RF data paths or engineered flat cables tailored for space constrained layouts, our team can assist in developing assemblies that meet both electrical and mechanical specifications.

Our engineering and manufacturing capabilities include:

- Micro coax assemblies with differential pair support up to 20+ Gbps

- Custom overmolding for strain relief and environmental sealing

- EMI-hardened ribbon and FPC assemblies for digital signaling

- Testing and qualification services for mission-critical environments

We help OEMs across defense, medical, industrial automation, and aerospace bring high-speed systems to market with optimized cable architectures.

Choose the Right Cable Architecture for Your Compact Design

Whether you’re building the next generation of embedded computing platforms, medical imaging devices, or space-saving industrial controllers, the cable architecture you select matters.

Work with Meritec to ensure your high-speed data paths are supported by interconnect solutions that balance performance, form factor, and long-term reliability.

Contact our team today to request a consultation or prototype quote.