VPX VS. VPX3 BACKPLANE SYSTEMS: CHOOSING THE RIGHT ARCHITECTURE FOR YOUR EMBEDDED DESIGN

Introduction: Embedded Performance Starts at the Backplane

In embedded computing systems, the backplane is more than just a connection hub, it’s the digital backbone. Whether you're designing military-grade mission systems, avionics control hardware, or edge computing nodes, the backplane architecture you choose will shape your system’s performance, scalability, and reliability.

At Meritec, we engineer connectivity platforms that meet modern embedded demands head-on. Our VPX3 Backplane System was developed to offer a rugged, high-speed alternative to traditional VPX architectures, one that simplifies integration while exceeding signal integrity expectations. If you’re deciding between VPX and VPX3, understanding the differences is critical to getting your embedded design right the first time.

What Sets VPX and VPX3 Apart?

VPX, based on the VITA 46 and VITA 65 OpenVPX standards, is a widely adopted high-speed interconnect system used in defense, aerospace, and rugged embedded environments. It supports both 3U and 6U form factors and enables system modularity through backplane-based configurations with traditional card edge connections.

Meritec’s VPX3 Backplane System builds on that same standard, but with a key difference: it replaces rear-transition module connectivity with a cable-based approach that enhances flexibility, reduces signal loss, and accelerates system prototyping. It’s fully compliant with VITA 46.0 and VITA 65 but eliminates some of the complexity and rigidity of fixed-backplane designs.

While both systems are rugged and capable, their underlying approach to interconnection leads to significant differences in how they're deployed.

Inside VPX3: A New Take on an Established Standard

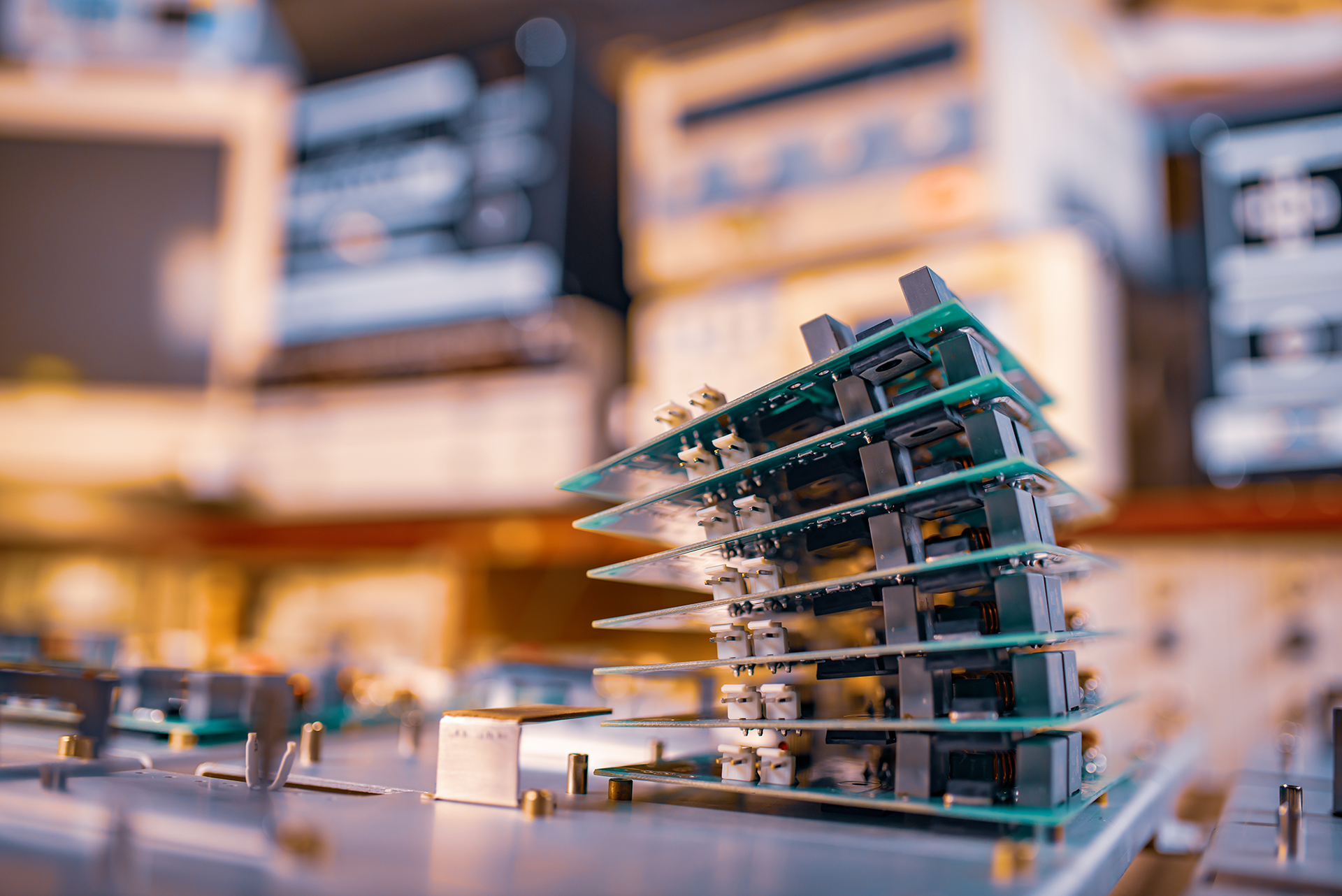

The VPX3 Backplane System features Meritec’s precision-engineered cabling and adapter boards, designed to connect VPX payload slots through discrete coaxial or twinax cables. These cables maintain controlled impedance and are optimized for low-skew, high-speed digital signals across multiple protocol types.

Unlike traditional VPX backplanes that require complex PCB routing for high-speed signals, VPX3 cables reduce EMI, simplify design changes, and enable faster deployment cycles. When signal clarity, reconfigurability, or tight layout constraints are at stake, VPX3 delivers measurable engineering advantages.

The system is available in standard and custom configurations, with options for low-profile panels, ruggedized shells, and VITA-compliant mechanical supports to ensure reliability under shock, vibration, and thermal stress.

How Each Architecture Performs in Practice

In traditional VPX-based systems, backplanes are custom-fabricated with signal traces etched into PCB layers. These backplanes serve as the fixed interface between modules, meaning that any change to system topology, slot assignments, signal protocols, or power layouts , can require significant redesign. For programs with fixed requirements and long lifecycle plans, this rigidity may be acceptable.

By contrast, VPX3 systems offer flexible, deployable interconnects through pre-engineered cables and adapters. Engineers can reconfigure I/O paths, upgrade modules, or adapt to protocol changes without redesigning the entire backplane. This is especially useful in rapid development environments, test platforms, and systems that evolve through multiple field updates.

In terms of signal integrity, VPX3’s controlled cable construction can outperform traditional backplanes, especially at data rates exceeding 10 Gb/s per pair. The physical separation between channels also helps reduce crosstalk and supports better EMI performance.

Designed for Demanding Applications

In aerospace, where space is limited and system upgrades are frequent, VPX3 allows platform integrators to re-route or repurpose payload slots without having to redesign a monolithic backplane. This reduces program costs and accelerates qualification cycles.

In military and defense applications, modularity and speed-to-field are key. VPX3 has been integrated into deployable control units, sensor fusion platforms, and embedded mission computers where ruggedness is a must but flexibility is also critical.

In

R&D and prototyping environments, VPX3 allows for system-level experimentation without the lead times of PCB manufacturing. New signal paths can be tested in hours, not weeks, and layout revisions don't require scrapping costly hardware.

Built for Engineers Who Need Options

Meritec’s VPX3 Backplane System is available in both standard and custom kit configurations. We offer panel-mount options for 3U payloads, breakout boards, cable assemblies with defined shielding, and system-level layout guidance.

Everything is designed with system integrators in mind, from the connector mating interfaces to the mechanical retention features. Our engineer-to-engineer collaboration model ensures you’ll get support during design, prototyping, and production rollout.

If your system requires rapid deployment, protocol evolution, or reconfigurable payload topology, VPX3 is a better fit than traditional backplanes. And if your application calls for a more fixed, low-maintenance architecture, traditional VPX may still be the right path.

Performance and Compliance That Matter

VPX3 assemblies are compliant with OpenVPX (VITA 65) and follow signal integrity standards laid out in VITA 46. They are tested for impedance control, continuity, EMI shielding effectiveness, and environmental resilience.

Meritec offers full documentation, 3D models, and datasheets to help with mechanical layout and signal planning. Our kits are built under IPC standards, and our ruggedized configurations are rated for thermal cycling, vibration, and field exposure.

The bottom line: you’ll know exactly how your interconnect system performs before it ever reaches deployment.

Customize Your VPX Solution with Meritec

No matter which direction you choose, traditional VPX or cable-based VPX3, Meritec provides the tools, products, and support to help your system succeed. We’ve delivered interconnect systems for mission-critical programs across aerospace, defense, and industrial markets. And with VPX3, we’re helping engineers solve design challenges faster, more flexibly, and with cleaner signals.

Explore or Contact Us

Learn more about Meritec’s board-to-board interconnect solutions:

Speak directly with our engineers about your embedded design: