WHAT IS A RUGGED I/O CONNECTOR? KEY FEATURES FOR HARSH APPLICATIONS

Introduction: More Than Just a Connector

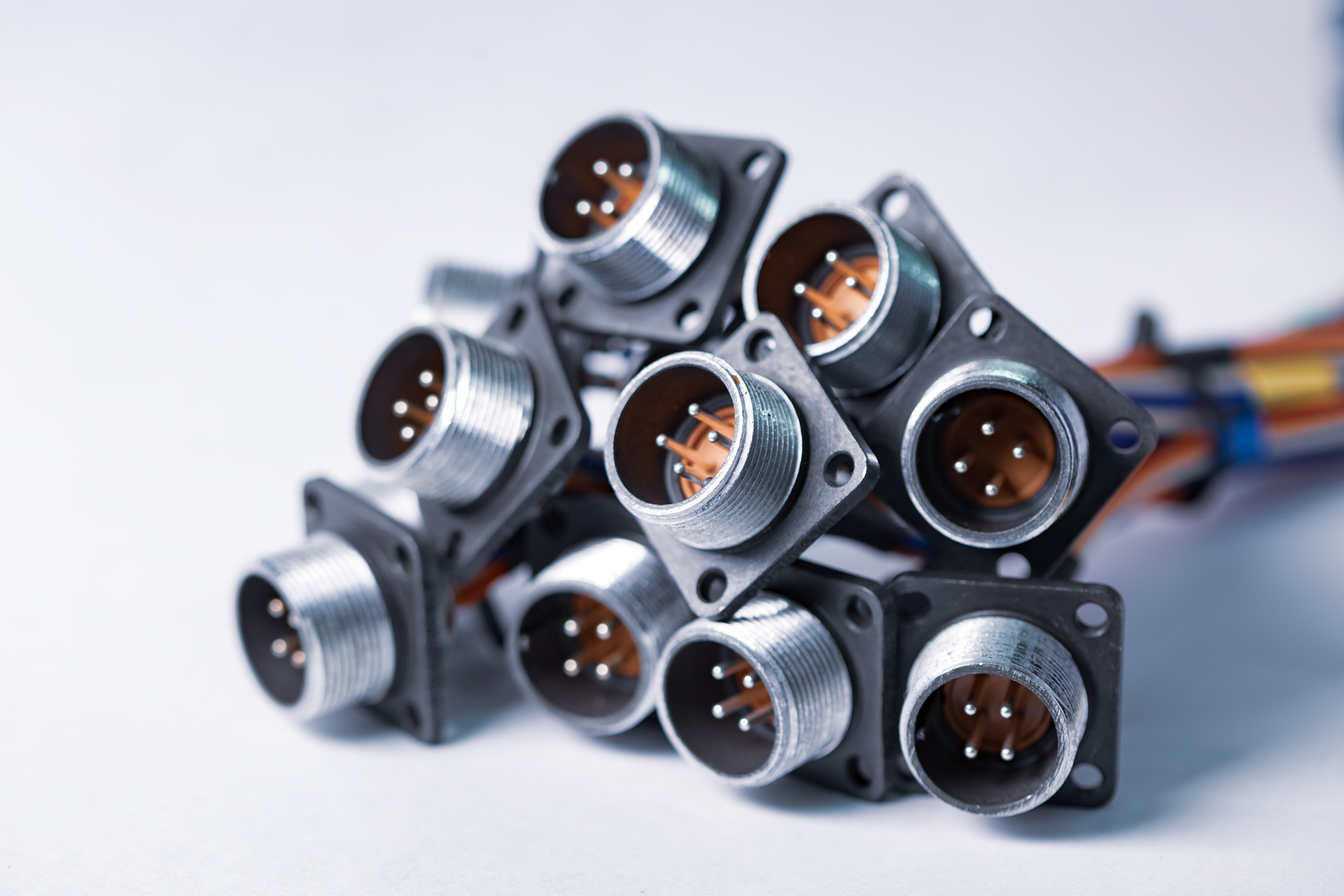

In rugged embedded systems, the performance of a device often comes down to the quality of its connections. When engineers design for harsh conditions, high vibration, wide temperature ranges, EMI, or environmental contaminants, they need an interconnect solution that won't just survive but will perform reliably under pressure.

Rugged I/O connectors are engineered to address these demands. Whether it’s a military communication system in a combat zone, a robotic control module in an oilfield, or a sensor array inside a fighter jet, these connectors ensure uninterrupted data and power flow where failure simply isn’t an option. At Meritec, we specialize in building rugged I/O connectors that not only meet these challenges but outperform traditional interconnects in even the harshest settings.

What Makes an I/O Connector "Rugged"

Rugged I/O connectors differ from standard connectors in how they handle physical and environmental stress. They're designed for durability, reliability, and data integrity in real-world conditions, not just in a controlled lab. This means resisting shock, vibration, moisture, chemicals, and EMI, all while maintaining electrical performance over time.

Key design priorities include mechanical retention, sealed housings, EMI shielding, and materials chosen specifically for corrosion resistance and thermal endurance. These connectors are often expected to operate in mission-critical systems where any failure could compromise safety, performance, or system control.

Meritec’s rugged I/O solutions, such as our Hercules® system and custom-engineered circular assemblies are field-tested to ensure this level of dependability, even when exposed to the most extreme conditions.

Built for Harsh Conditions: Design Principles That Matter

The first priority in rugged connector design is choosing materials that can perform under pressure. That means shells built from aircraft-grade aluminum, stainless steel, or composite alloys, often plated for corrosion resistance. Internally, contact systems are designed to maintain low resistance and high cycle life.

The connector geometry also plays a critical role. Meritec offers both straight and right-angle options to fit into compact enclosures and tight layouts. These connectors feature mechanical locking systems, such as bayonet or threaded couplings, to prevent accidental disconnection under vibration or impact.

Cables used in ruggedized I/O assemblies are equally important. They must offer abrasion resistance, flexibility under repeated motion, and support high-speed signal transmission. Jackets are selected based on the environment, polyurethane or Teflon® for chemical resistance, FEP or silicone for thermal resilience.

EMI Shielding and Signal Integrity

Maintaining clean, uninterrupted signals in rugged environments requires more than just insulation. It demands precision-engineered shielding that prevents electromagnetic interference from corrupting sensitive data.

Meritec’s rugged I/O assemblies include full 360-degree shielding with metal backshells, grounded drain wires, and impedance-matched differential pairs. These design elements help embedded systems meet strict EMI and EMC compliance standards, even when operating near RF equipment, switching power supplies, or other noise sources.

By maintaining low skew and tightly controlled impedance, we ensure high-speed protocols like USB 3.1, 10G Ethernet, PCIe, and SATA function properly, even when deployed in unpredictable field conditions.

Environmental Sealing and IP Protection

In real-world deployments, systems may be exposed to water, dust, oil, or corrosive fluids. Meritec's rugged I/O connectors feature sealing that meets or exceeds IP67 and IP68 ratings, depending on configuration. These seals protect not only the contact interface but also the cable-entry point, ensuring long-term resistance to moisture ingress and environmental degradation.

Sealed connector solutions often include molded backshells, compression gaskets, and environmental caps that protect unmated connectors. When system uptime is critical, these extra layers of defense help eliminate potential points of failure.

Application Spotlight: Rugged UAV Payloads

A defense contractor integrating a sensor payload into an unmanned aerial vehicle (UAV) needed a lightweight, shielded connector that could carry power and data through the aircraft’s internal control bus. The connector had to be vibration-resistant, IP-sealed, and compatible with the aircraft’s avionics power profile.

Meritec delivered a Hercules®-based solution, incorporating hybrid signal and power contacts in a circular MIL-style shell. The cable was overmolded for strain relief and fully shielded for EMI suppression. After passing MIL-STD environmental tests, the connector was deployed into a high-volume UAV fleet with no reported failures.

This kind of rugged application is where Meritec’s experience and engineering precision make the difference.

Customization for Embedded System Needs

No two rugged systems are the same. That’s why Meritec works directly with engineers to develop connector solutions that match their size constraints, signal requirements, and durability targets.

We offer custom pinouts, hybrid power/data configurations, specialized strain reliefs, and connector shells tailored to your mounting or enclosure geometry. Whether your system needs to pass military environmental standards, meet medical device sealing specs, or operate on mobile industrial platforms, Meritec delivers solutions built to spec and tested to perform.

Proven in the Field, Ready for What’s Next

Our rugged I/O connectors are trusted in applications ranging from ground vehicles and aircraft to drilling rigs and automated manufacturing cells. We provide fast-turn prototyping, complete electrical and mechanical documentation, and full support through design verification and production.

Engineers choose Meritec because we don’t just sell connectors, we solve interconnect challenges in high-stakes environments. Our products are backed by testing, documentation, and real-world validation to ensure that once they’re deployed, they stay connected.

Conclusion: Dependability by Design

A rugged I/O connector isn’t defined by one feature, it’s the result of careful engineering, durable materials, and real-world validation. Meritec builds connectors that protect signals, endure abuse, and integrate into the most advanced embedded systems.

When the conditions are harsh and performance is non-negotiable, Meritec’s rugged I/O connectors are designed to deliver. Talk to our engineers to get started on your next project.

Explore or Contact Us

Learn more about Meritec’s board-to-board interconnect solutions:

Speak directly with our engineers about your embedded design: