MILITARY GRADE INTERCONNECT SOLUTIONS FOR NEXT-GEN DEFENSE ELECTRONICS

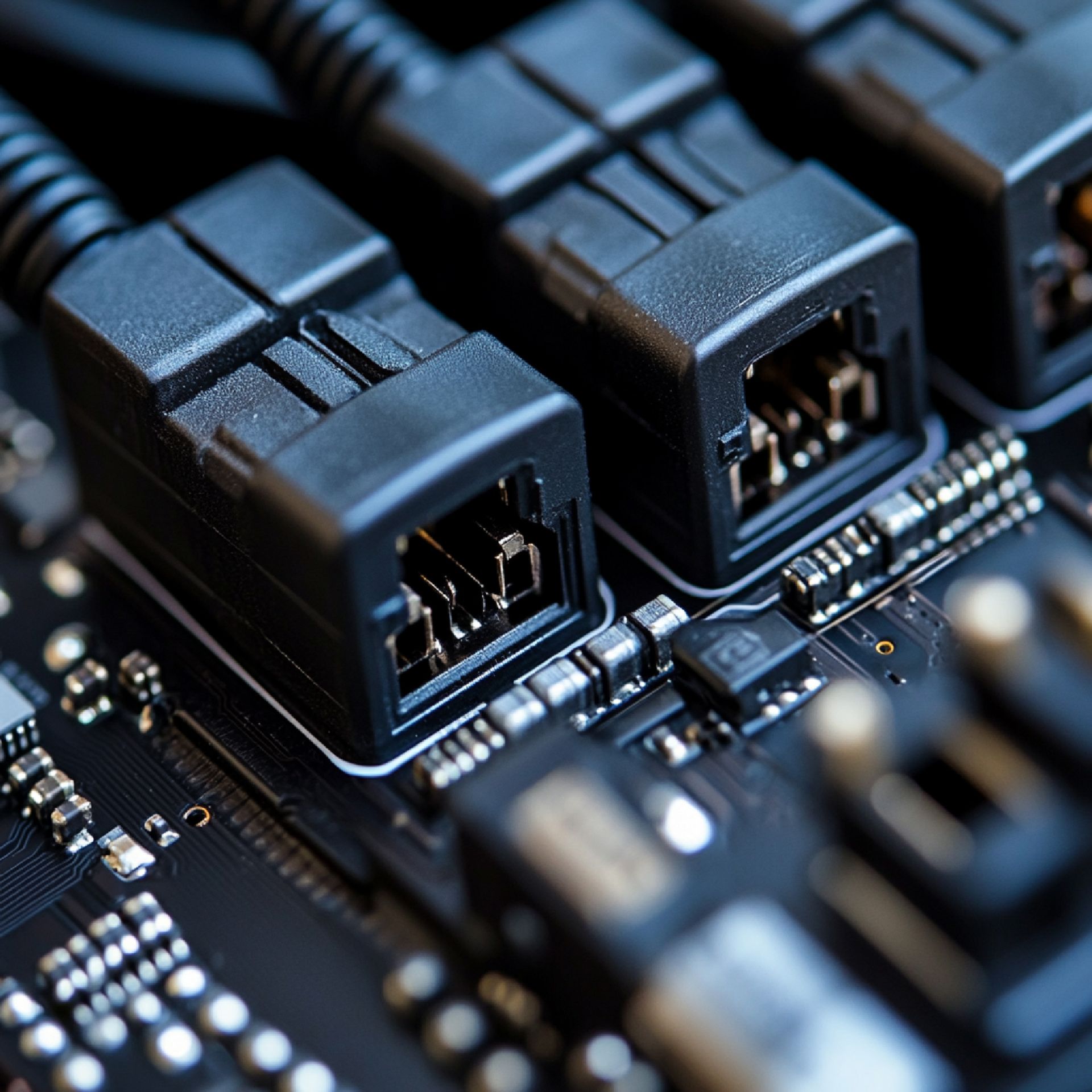

Today’s defense electronics are evolving rapidly systems are faster, smaller, and must operate in increasingly hostile environments. From ground vehicles and drones to satellite uplinks and C5ISR platforms, high performance interconnect solutions are essential for ensuring mission success.

These aren’t just cables and connectors. Military grade interconnects are engineered components that uphold signal integrity, resist harsh environmental threats, and deliver reliability under extreme pressure. As defense applications expand into electronic warfare, unmanned systems, and data centric operations, ruggedized interconnects become foundational elements in system design.

At Meritec, we develop and manufacture interconnect systems that exceed the rigorous demands of modern defense electronics, with performance proven across air, land, sea, and space.

Defining Military Grade Interconnect Requirements

Defense applications push every component to its limit. Interconnects must operate consistently across a wide temperature range, endure physical shocks, and mitigate environmental intrusions. Requirements include:

- Thermal durability: Reliable operation from -55°C to +125°C or more

- EMI/RFI protection: Shielding to preserve data integrity in contested signal environments

- Mechanical strength: Resistance to constant vibration, shock, and impact

- Ingress resistance: Protection against dust, sand, moisture, and chemicals

- Compliance: Adherence to military specifications like MIL-STD-810, MIL-DTL-38999, and MIL-STD-461

For systems involved in rapid targeting, autonomous operations, and secure communication, robust interconnects are not optional they are mission-critical.

Applications Driving Innovation

Tactical Communication Platforms

From encrypted radios to mobile satellite uplinks, secure and uninterrupted data flow is essential. Connectors in these systems must ensure EMI shielding, watertight sealing, and field serviceability.

Unmanned Systems (UAVs, UGVs, USVs)

Lightweight interconnects with high pin density support real-time control, imaging, navigation, and secure telemetry. Miniaturization is key, but performance cannot be compromised.

Electronic Warfare and Radar

These systems generate and receive high-frequency signals that demand ultra-low-loss, phase-stable cabling from sensor arrays to processing cores, all while withstanding significant thermal and mechanical stress.

C5ISR Systems

Complex data fusion and battlefield awareness platforms demand scalable, sealed connectors capable of combining power, data, RF, and fiber in single-interface designs.

Military Vehicles and Weapon Systems

Harsh vibration, heat, exposure to fuel and chemicals, and terrain-induced shock loads make durability and strain relief essential in connectors installed in tanks, personnel carriers, and mobile artillery.

Materials Built for Harsh Environments

Material selection defines the durability and reliability of military interconnects. Meritec incorporates:

- High-performance polymers such as PTFE, FEP, and TPE for flexible jacketing and insulation.

- Conductive shielding using foil and braided copper to block EMI and RFI.

- Rugged housings of anodized aluminum or stainless steel with corrosion-resistant coatings.

- Sealing technologies including O-rings, molded boots, and venting elements for pressure equalization.

Whether facing high humidity, salt spray, or exposure to jet fuel, these materials ensure sustained performance without degradation.

Miniaturization Meets Mission Readiness

As defense systems shrink and integrate more functions per cubic inch, interconnects must evolve to fit smaller footprints without compromising electrical or mechanical performance.

Meritec designs high-density board-to-board and cable-to-board solutions that incorporate:

- Controlled impedance for high-speed data

- Differential pair support for reduced crosstalk

- Space-saving form factors for UAVs, wearables, and modular computing nodes

This enables compact systems to process and transmit vast data volumes efficiently and securely, critical in edge computing and battlefield surveillance.

Environmental & Electromagnetic Protection

Defense interconnects must thrive in environments ranging from arctic tundras to desert theaters. Common stressors include temperature fluctuations, debris exposure, and electromagnetic interference.

Meritec addresses these with:

- IP67/IP68-rated sealing

- Shielding layers to block EMI/RFI

- Chemically resistant materials

- Secure latching or threaded coupling mechanisms

These measures ensure signal reliability and operational safety, even in mission-critical deployments.

Military Standards and Compliance Overview

Meritec's defense products meet and often exceed the industry's strictest standards:

| Standard | Purpose |

|---|---|

| MIL-DTL-38999 | Circular connectors for harsh environments |

| MIL-STD-810 | Environmental engineering considerations and lab testing |

| MIL-STD-461 | Electromagnetic interference (EMI/RFI) standards |

| IPC/WHMA-A-620 | Cable and wire harness assembly requirements |

| AS9100 | Aerospace/defense quality management standard |

All Meritec products destined for defense are manufactured under certified processes with complete traceability and quality documentation.

Custom Engineering for Tactical Advantage

Meritec doesn’t stop at off-the-shelf solutions. We partner with OEMs and integrators to create mission-specific designs that align with your mechanical and electrical parameters.

Our capabilities include:

- In-house overmolding and termination

- Rapid prototyping and short-run production

- Complex hybrid assemblies (power, signal, RF, fiber)

- EMI gasketing and shielding enhancements

- 3D modeling and mechanical fit analysis

From concept to deployment, we provide end-to-end engineering support.

Partnering with Defense Innovators

Meritec collaborates with major defense contractors, OEMs, and government agencies to co-develop interconnect solutions on tight deadlines and evolving specs. We understand the procurement, testing, and certification landscape, ensuring your path from prototype to production is smooth and compliant.

Whether you're developing the next generation of guided missile systems, refreshing vehicle electronics, or deploying tactical edge nodes, Meritec is your partner in performance.

Frequently Asked Questions (FAQ)

What makes a connector “military-grade”?

Military grade connectors are specifically designed to meet military performance standards. They endure extreme conditions, resist EMI/RFI, and comply with MIL STD certifications.

Can Meritec customize connectors for specific military applications?

Yes. Meritec frequently partners with defense OEMs to create tailored cable assemblies and connector solutions that meet exact environmental, mechanical, and electrical requirements.

Are Meritec products compliant with ITAR or other defense regulations?

Meritec maintains ITAR registration and complies with relevant U.S. defense manufacturing requirements, including controlled documentation and secure domestic production.

How does Meritec ensure quality in military connector production?

All defense products are manufactured under AS9100 and ISO certified processes with full traceability, rigorous inspection, and environmental testing.

What industries beyond defense use rugged Meritec interconnects?

In addition to defense, Meritec serves aerospace, space, industrial automation, and transportation sectors anywhere reliability and durability are non-negotiable.

Ready to Support Your Next Mission

Meritec's military-grade interconnect solutions keep critical systems running in the harshest environments. From high-speed data transmission to electromagnetic shielding and miniaturized connectors, we engineer every component for performance under pressure.

Connect with our engineering team to explore defense-ready solutions for your next project.